Evaluate the point of contraflexure:

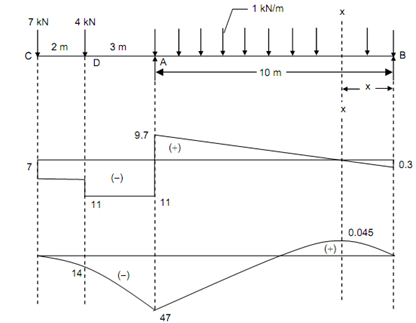

An overhanging beam of 15 m span is carrying a consistently distributed load of 1 kN/m over the length of 10 m at a distance 5 m from the left free end and point loads 7 kN and 4 kN, at free end and at a distance 2 m from the free end, respectively. Sketch the BMD and SFD for the beam. Situate the point of contraflexure.

Solution

Taking moments around B and equating to zero,

R A × 10 - (7 × 15) - (4 × 13) - (1 × 10 × (10/2) ) = 0

RA = 20.7 kN

and RB = 7 + 4 + (1 × 10) - 20.7 = 0.3 kN

Shear Force (beginning from the left end C)

SF just right of C, FC = - 7 kN

SF just left of D, FD = - 7 kN

SF just right of D, FD = - 7 - 4 = - 11 kN

SF just left of A, FA = - 11 kN

SF just right of A, FA = - 11 + 20.7 = 9.7 kN

SF just left of B, FB = + 9.7 - (1 ×10) = - 0.3 kN = Reaction at the support B.

Bending Moment

BM at B, MB = 0

BM at A, MA

= (0.3 × 10) - (1 × 10 × (10/2)) = - 47 kN m

BM at D, MD = - (7 × 2) = - 14 kN m

BM at C, MC = 0

let a section XX at a distance x from the end B as illustrated in Figure.

Shear force at section XX,

Fx = - 0.3 + 1(x)

For maximum bending moment, shear force will be zero.

- 0.3 + x = 0

x = 0.3 m

We have,

Mx = + 0.3(x) - 1 × (x) ×(x/2) = 0.3x - x 2 /2

Mmax = 0.3 × (0.3) - ((0.3)2 /2) = + 0.045 kN m

Figure

This is seen that the maximum negative bending moment take place at A and maximum positive bending moment take place at a distance 0.3 m from the right end B.

Mmax (positive) = + 0.045 kN m

Mmax (negative) = - 47 kN m

Point of Contraflexure

This is observed that the BM changes sign among A and B,

BM at any section XX,

Mx = 0.3 x - x 2 / 2

Equating this to zero,

0.3 x - x2/2 = 0

0.6 x - x2 = 0

∴ x = 0.6 m

Thus, the point of contraflexure is at a distance of 0.6 m from the right end B.