Determine the maximum stress intensities:

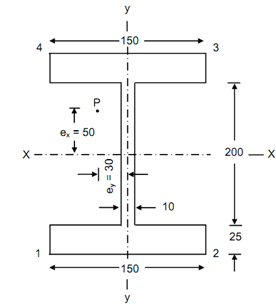

A rolled steel I-section, flanges 150 mm wide & 25 mm thick, web 200 mm long & 10 mm thick is utilized to carry & axial load of 800 kN. The load line is eccentric, 50 mm above XX & 30 mm to the left of yy. Determine the maximum & minimum stress intensities in the section.

Figure

Solution

Area of the cross-section, A = 2 × (150 × 25) + (200 × 10) = 9500 mm2

Moment of inertia about XX-axis,

I xx = 150 × 250/12 - 140 (20)3/12

= 8565 × 104 mm4

Moment of inertia about YY-axis,

I yy =2 × (25 × 1503 )/ 12 -200 (10)3/12 = 1407 × 104 mm4

Eccentricity,

ex = 50 mm

ey =- 30 mm

Vertical load, W = 800 kN

Direct stress at any point, f0 = P/A =800 × 103/9500

= 84.2 N/mm2

Maximum bending compressive stress shall take place at edge 4 of the section in Figure

= ( fb )4 = ((P × ex /Ixx) × y )+(( P × ey/ I yy )× x)

= (800 × 103 × 50/ 8565 × 104) × (- 125) +( 800 × 103 × (- 30) /1407 × 104) × 75

= 186.4 N/mm2

Maximum bending tensile stress shall take place at edge 2 at the section.

( f b )2 =( 800 × 10 3 × 50)/( 800 × 104 ))× (- 125)

+( 8565 × 103 (- 30)/ (1407 × 104 ))× 75

= - 18.64 N/mm2

In the section Resultant stress would be as follows:

Maximum at corner 4 = 84.2 + 186.4 = 270.6 N/mm2

Minimum at corner 5 = 84.2 - 186.4 = - 102.2 N/mm2 (tensile)