Time and Cost Analysis

This discusses about certain basic activities that must be carried out in a factory to convert raw materials into finished products. These activities broadly are Processing and assembly operations, Material handling, Inspection and testing and Coordination and control.

The machining times for various machining processes and the importance of it is explained.

The machining time in turning (t) is as

t = L + L0 /2 f N

The machining time in milling T in minutes can be calculated as

T = (L × n)/ f Z N minutes

Time for drilling the hole = L/ f N minutes

Machining Time = Depth of hole to be bored in mm minutes/ N × feed/rev

where, N = No. of revolutions per min. of machine spindle or work.

In boring operation the machining time is calculated the same manner as in turning. It is given by the following relation :

Machining Time = Depth of hole to be bored in mm minutes/ N × feed/rev

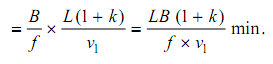

where, N = No. of revolutions per min. of machine spindle or work. Machining time for shaping can be calculated as below.

No. of cycles required (n) = Shaping width / Feed per cycle f

= B/f

Machining time = No. of cycles × time required for each cycle

The machining time (T) in cylindrical grinding can be calculated from the following relationship.

T = (L . P . K )/ ( f . N . t) min .

The total production cost of machined components is made up of the following components : material cost, labour cost, overhead cost, tool cost and cost of percent of the total cost. But the influence of tools on the other costs is considerable. It is often possible that the tool cost is increased but the total production cost is reduced considerably because of the influence of the tool on other aspects of cost.

The costs that go into machining a part can be broken into three categories as Material removal cost, Tool cost and Non-productive cost

Total machining cost = Material removal cost + Tool cost + Non-productive cost. The tool cost is made up of

(a) Tool change cost (TCC) or cost for indexing the insert

(b) Tool regrinding cost (TRC)

(c) Tool original cost (TOC)

(d) Tool inventory cost (TIC)

Total tool cost = TCC + TRC + TOC + TIC