Procedures for starting and ground running:

Before starting and ground running any gas turbine powered aircraft, several considerations must be taken into account. The first and most important is the safety of personnel, aircraft and equipment involved in the run. Secondly the safety of personnel, aircraft, equipment and buildings close to but not involved in the run, and thirdly the safety of the engine itself.

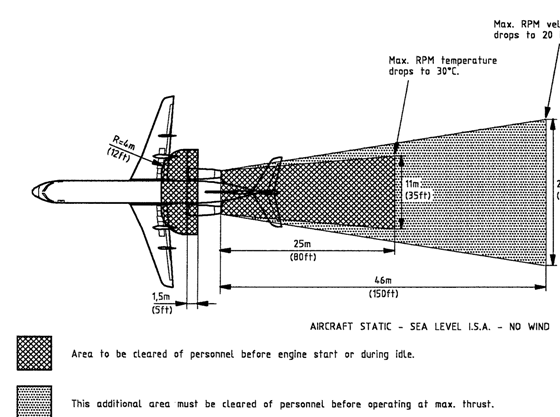

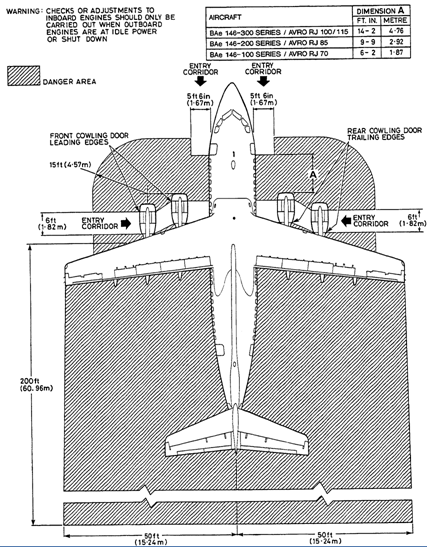

The aircraft maintenance manual (AMM) will show the danger areas associated with the aircraft and these must be observed at all times. To alert other personnel of the need to take precautions safety signs should be positioned. Ideally engine ground runs should be carried out in a designated area which will to a large extent assist safety. There may however be occasions when these designated areas are not available. Precautions to protect personnel, aircraft and equipment must still be observed.

Particular attention should be paid to the positioning of the aircraft and its ground support equipment (GSE). The aircraft should be facing into wind and securely chocked (possibly with the front and rear chocks tied together). The visual and free movement of both compressor and turbine should be checked, and the engine air intake examined for loose articles. The areas to the front and rear of the aircraft should be checked for loose articles and spilt fuel, which could cause a hazard to the aircraft during the run.

The technical log must be checked to ensure that no outstanding entries will jeopardise the operation or function of other aircraft systems. Other entries may require functional checks to be carried during the ground run, which may also require involvement in the run of other tradesmen. Ground support equipment should be positioned to ensure their safe operation and movement, if required, during the start and run.

STARTING

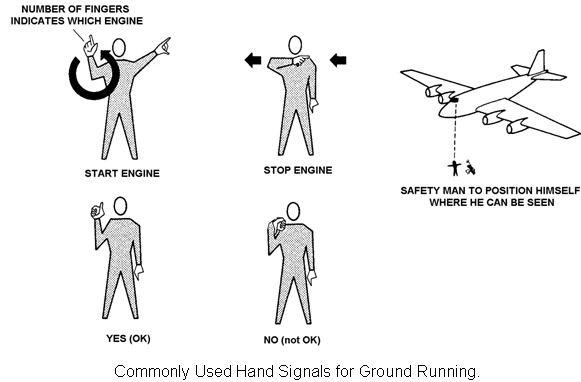

Prior to starting the engines all personnel involved must be made aware of their responsibilities and role during the run. If hand signals are to be used they should be agreed and understood by all concerned. All personnel outside the aircraft must wear ear-defenders, if possible one or more of the external team should have an intercom headset for direct communication with those inside.

The person(s) operating the controls during starting and running must be familiar with the controls, instruments and limitations associated with the engines. In particular they should be aware of the limitations imposed upon the engines turbine temperature during start.

If the start is to be made from the aircraft batteries, ensure they are fully charged. If a ground power unit is to be used, it must be appropriate for the aircraft and must be correctly connected. If the starter requires air, then the APU will be required or a suitable air-cart attached correctly to the aircraft.

Starting procedures will vary depending on aircraft type and installation hence, the AMM must always be referred to. The example that follows is however typical and will serve as a general guide:

1. Set all controls and switches etc. as per AMM.

2. Switch ‘on' electrical power.

3. Carry out relevant flightdeck safety checks i.e. Brakes ‘on', Engine fire warning tests etc.

4. Low pressure fuel valve (LP) [sometimes called the LP cock] check ‘open'.

5. Contact Air Traffic Control on the radio, giving location, type of run and number of people on board.

6. Switch ‘on the aircraft booster pumps.

7. Confirm ‘clear to start' from safety man.

8. Select start master switch to ‘on', the aircraft systems will be put into starting mode.

9. Select ‘start'

At this point the starting sequence becomes semi automatic.

10. The starter begins to rotate the compressor (HP if multi shaft) to provide a flow of air through the engine.

11. The engine ignitors are energised.

Observing the engine's RPM, when this reaches a speed of approximately 10 -20%, advance the high pressure fuel valve to open either by moving the throttle or the HP cock lever (on aircraft with a separate lever) to the ‘fuel on' or ground idle (GI) position. The engine speed will increase as the starter motor continues its acceleration; fuel will be supplied to the atomisers and will be burnt in the combustion chambers. ‘Light up' will occur which will be indicated by a rapid rise in Exhaust Gas Temperature (EGT).

12. The rise in gas temperature will cause the air within the combustion chamber to expand which when passed through the turbine will assist the acceleration.

13. During this phase the oil pressure should start to rise.

14. As the engine accelerates it will reach a point called ‘the self-sustaining speed'; this is the minimum speed at which the engine can run unassisted.

15. Once above self-sustaining speed the starter and ignition will cut out automatically, and the engine will accelerate to ground idle under the control of the fuel system.

It is during this phase of the acceleration when there is a great risk of exceeding the maximum starting temperature of the engine, so vigilance is required to monitor the EGT.