Engine indication systems in Aircraft:

Engine indications are very important to the crew of a powered aircraft, as they indicate one of the primary parameters needed for flight.

There are three types of indications:

1. Performance indications such as thrust (Engine Pressure Ratio EPR) and Revolutions Per Minute (RPM).

2. Operation indications such as Turbine Temperature indications, fuel flow, oil pressure and temperature.

3. Discrete indications which put ‘ON' a warning annunciator such as low oil pressure, fuel low pressure engine overspeed etc.

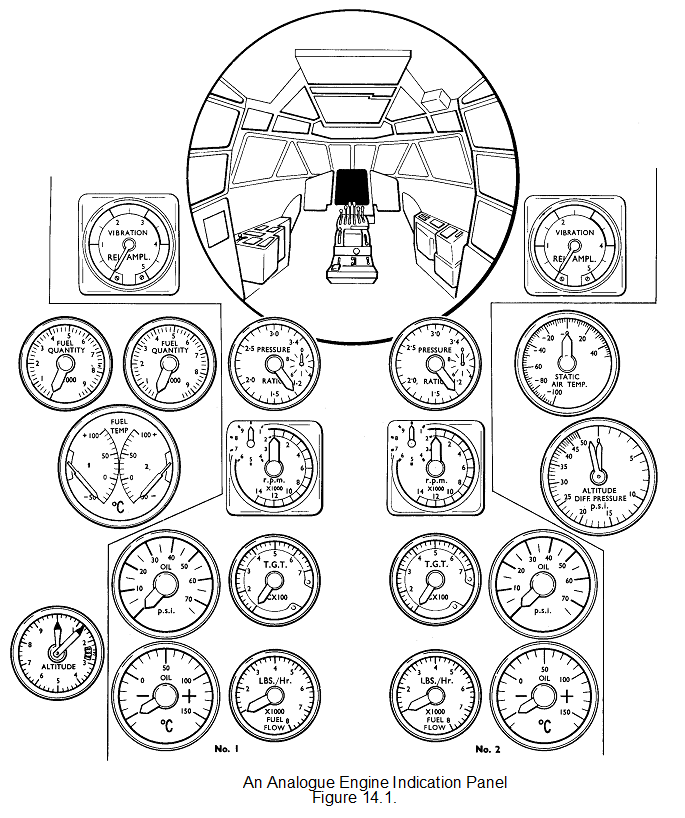

The engine instruments on most modern commercial aircraft will invariably be located on the main instrument panel in the centre, so that they are visible to both pilots. The instruments are laid out in a logical pattern so that the main thrust indicator is at or near the top of the indications. The indicators will be in vertical columns for each engine and like indicators in rows.

When a flight engineer is carried he will have a panel with some of the primary indications and all of the secondary and discrete indicators. He may also have a duplicate set of thrust levers so that he can trim engines when required.

Until fairly recently the majority of aircraft used analogue gauges (sometimes referred to as clockwork gauges) These had moving pointers or strips which indicated the parameter being monitored.

The modern trend is to replace the analogue instruments with electronic instruments that use LED, liquid crystal or cathode ray screens to display the engine parameters, often not displaying continuously all the information, but to highlight when a fault has occurred or when asked for by the crew. These types of instrument do not usually retain the last indication after an accident, however the electronic box powering them will inform the flight data recorder and/or retain the information in its own memory.