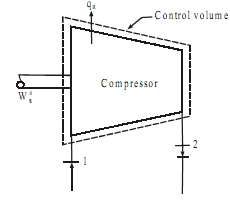

Centrifugal air compressor:

A centrifugal air compressor delivers 15Kg of air per minute. The outlet and inlet conditions are

At inlet: Velocity = 5m/sec, enthalpy = 5KJ/kg

At outlet: Velocity = 7.5m/sec, enthalpy = 173KJ/kg

Heat loss to the cooling water is 756KJ/min find:

(1) The power of motor required to drive compressor.

(2) Ratio of inlet pipe diameter to outlet pipe diameter when specific volumes of air at inlet and outlet are 0.5m3/kg and 0.15m3/kg correspondingly. Inlet and outlet lines are at same level.

Sol: Device: Centrifugal compressor Mass flow rate mf = 15Kg/min Condition at inlet:

V1 = 5m/sec; h1 = 5KJ/kg

Condition at exit:

V2 = 7.5m/sec; h3 = 173KJ/kg

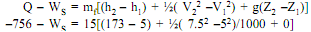

Heat loss to cooling water Q = -756 KJ/min

From SFEE

WS= -3276.23KJ/min = - 54.60KJ/sec .......ANS

(negative sign indicate that work done on the system) Thus the power of motor required to drive the compressor is 54.60KW

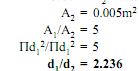

Mass flow rate at inlet = Mass flow rate at outlet = 15kg/min = 15/60 kg/sec

Mass flow rate at inlet = mf1 = A1.V1/ ν1

15/60 = A1 × 5/0.5

A1 = 0.025m2

Now; Mass flow rate at outlet = mf2 = A2.V2/ν2

15/60 = A2 × 7.5/0.15

Thus the ratio of inlet pipe diameter to outlet pipe diameter is 2.236