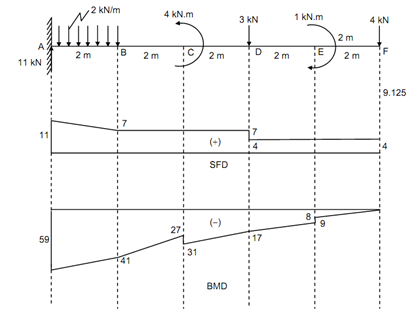

Cantilever beam - shear force diagrams:

Illustrate the shear force & bending moment diagrams for the cantilever beam illustrated in Figure.

Figure

Solution

Reaction at the support A,

RA = (2 × 2) + 3 + 4 = + 11 kN

Shear Force (Beginning from the Left End A)

SF at A, FA = + 11 kN

SF at B, FB = + 11 - (2 × 2) = + 7 kN

SF just left of D, FD = + 7 kN

SF just right of D, FD = + 7 - 3 = + 4 kN

SF just left of F, FF = + 4 kN = load at F

Bending Moment (Beginning from the Right End F)

BM just right of E, M E = - 4 × 2 = - 8 kN-m

BM just left of E, M E = - 8 - 1 = - 9 kN-m

BM at D, M D = - 4 × 4 - 1 = - 17 kN-m

BM just right of C, M C =- (4 × 6) - 1 - (3 × 2) =- 31 kN-m

BM just left of C, M C =- 31 + 4 =- 27 kN-m

BM at B, M B = - (4 × 8) - 1 - (3 × 4) + 4 = - 41 kN-m

BM at A, MA =- (4 × 10) - 1 - (3 × 6) + 4 - (2 × 2 × (2 /2)) =- 59 kN-m