Reference no: EM131361077

New England Foundry

For more than 75 years, New England Foundry, Inc. (NEFI), has manufactured wood stoves for home use. In recent years, with increasing energy prices, president George Mathison has seen sales triple. This dramatic increase has made it difficult for George to maintain quality in all his wood stoves and related products. Unlike other companies manufacturing wood stoves, NEFI is in the business of making only stoves and stove-related products. Its major products are the Warmglo I, the Warmglo II, the Warmglo III, and the Warmglo IV. The Warmglo I is the smallest wood stove, with a heat output of 30,000 BTUs, and the Warmglo IV is the largest, with a heat output of 60,000 BTUs. The Warmglo III outsold all other models by a wide margin. Its heat output and available accessories were ideal for the typical home. The Warmglo III also had a number of other outstanding features that made it one of the most attractive and heat-efficient stoves on the market. These features, along with the accessories, resulted in expanding sales and prompted George to build a new factory to manufacture the Warmglo III model. An overview diagram of the factory is shown in Figure D.6. The new foundry used the latest equipment, including a new Disamatic that helped in manufacturing stove parts. Regardless of new equipment or procedures, casting operations have remained basically unchanged for hundreds of years. To begin with, a wooden pattern is made for every cast-iron piece in the stove. The wooden pattern is an exact duplicate of the cast-iron piece that is to be manufactured. All NEFI patterns are made by Precision Patterns, Inc. and are stored in the pattern shop and maintenance room.

Next, a specially formulated sand is molded around the wooden pattern. There can be two or more sand molds for each pattern. The sand is mixed and the molds are made in the molding room. When the wooden pattern is removed, the resulting sand molds form a negative image of the desired casting. Next, molds are transported to the casting room, where molten iron is poured into them and allowed to cool. When the iron has solidified, molds are moved into the cleaning, grinding, and preparation room, where they are dumped into large vibrators that shake most of the sand from the casting. The rough castings are then subjected to both sandblasting to remove the rest of the sand and grinding to finish some of their surfaces. Castings are then painted with a special heat-resistant paint, assembled into workable stoves, and inspected for manufacturing defects that may have gone undetected. Finally, finished stoves are moved to storage and shipping, where they are packaged and transported to the appropriate locations. At present, the pattern shop and the maintenance department are located in the same room. One large counter is used by both maintenance personnel, who store tools and parts (which are mainly used by the casting department), and sand molders, who need various patterns for the molding operation. Pete Nawler and Bob Dillman, who work behind the counter, can service a total of 10 people per hour (about 5 per hour each).

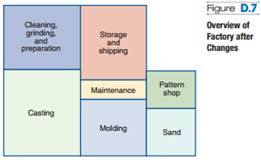

On average, 4 people from casting and 3 from molding arrive at the counter each hour. People from molding and casting departments arrive randomly, and to be served, they form a single line. Pete and Bob have always had a policy of first come, first served. Because of the location of the pattern shop and maintenance department, it takes an average of 3 minutes for an individual from the casting department to walk to the pattern and maintenance room, and it takes about 1 minute for an individual to walk from the molding department to the pattern and maintenance room. After observing the operation of the pattern shop and maintenance room for several weeks, George decided to make some changes to the factory layout. An overview of these changes appears in Figure D.7. Separating the maintenance shop from the pattern shop would have a number of advantages. It would take people from the casting department only 1 minute instead of 3 to get to the new maintenance room. The time from molding to the pattern shop would be unchanged. Using motion and time studies, George was also able to determine that improving the layout of the maintenance room would allow Bob to serve 6 people from the casting department per hour; improving the layout of the pattern department would allow Pete to serve 7 people from the molding shop per hour.

Discussion Questions

1. How much time would the new layout save?

2. If casting personnel were paid $9.50 per hour and molding personnel were paid $11.75 per hour, how much could be saved per hour with the new factory layout?

3. Should George have made the change in layout?

|

To what extent does the websites use technical language

: To what extent does the Websites use technical language? Do you see any examples of jargon? List examples. How long is the average sentence in each Website? How long is the average paragraph?

|

|

Complete the next iteration using the stepping-stone method

: Complete the next iteration using the stepping-stone method. Calculate the "total cost" incurred if your results were to be accepted as the final solution

|

|

What is the energy of the fermi level

: Consider excitations from level εi = -4 eV with 1025 states/m3 to level ε j = -2.5 eV with 1024 states/m3 in a semiconductor at 295 K. (Treat the states as band-edge equivalent states if you wish.)

|

|

What are causes of change in equity

: Last year the Chester company increased their equity. In 2015 their equity was $49,360. Last year (2016) it increased to $53,929. What are causes of change in equity? Check all that apply. Select: 3 Save Answer Plant Improvements of $9,580 An account..

|

|

How much time would the new layout save

: How much time would the new layout save? If casting personnel were paid $9.50 per hour and molding personnel were paid $11.75 per hour, how much could be saved per hour with the new factory layout

|

|

Calculate market capitalization and market-to-book ratio

: Amazon currently has the following financial information: a share price of $766, 474 million shares outstanding, book value of equity of $13.384B, Net income of $596M At the end of the previous fiscal year, Amazon had book value of equity of $10.74B ..

|

|

Create a newsletter for your community

: Define public health - Explain the historical development of public health and identify careers within public health - create a newsletter for your community.

|

|

Estimate density of conduction electrons in the conduction

: Suppose that the Fermi level is 0.50 eV equation 23.15 below the conduction band in a certain semiconductor. Estimate the density of conduction electrons in the conduction band for temperatures of 50 K, 200 K, and 600 K.

|

|

Write a ppaer about sustainable packaging

: Write a ppaer about Sustainable Packaging. This paper should be a minimum of 2000 words, and a maximum of 3000 words, excluding title and references (Papers outsides these limits will be penalized).

|