Time Study - Process Design

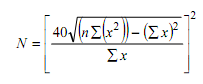

Time study by stopwatch or micro-motion analysis is the original method of work measurement devised by Taylor and his followers, and is still routinely used for the establishment of standard times wherever routine, repetitive work is entailed. Assuming the job has previously been method-studied, its record is first examined and the sequence broken into elements. These elements (typically 5 to 30 seconds) are distinct parts of the job, which allow the separation of effective working time and ineffective time, and allow accurate rating (since the worker's pace may change for certain elements). They also allow the identification of arduous elements, to which appropriate allowances may be added, and facilitate the compilation of standard data for frequently recurring elements. Because there is a natural variability in work pace it is necessary to measure the element several times in order to establish a reliable average observed time. Clearly, the greater the number of measurements (sample size, N), the more accurate will be the calculated observed time, but the cost of the study will increase. Fortunately, since the variability typically follows a normal distribution, we can take advantage of statistical analysis. If, as is typical, an estimate within ±5 per cent of the true value and 95 per cent confidence level is acceptable, then the following means can be used to determine the sample size. First of all a small preliminary sample of 'n' of measurements is taken, and the following calculation performed to determine the full sample size, 'N'.

Where x = the individual measurements

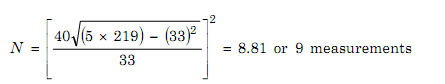

For example, if a preliminary sample of five measurements is taken in units of 0.01 minutes: 7, 6, 7, 7, 6. the full-study sample size is then calculated as:

The measurements are then made, simultaneously assessing the rating of the worker's pace, and the standard time for the job calculated as indicated earlier.