Siting Departments for Process Layout - Service Operations

In determining the relative position of service departments the costs of movement may be less important than other, less-quantifiable considerations. For example, it may be important for customer reception to be close to the main entrance; it may be desirable to separate customers from back-office staff, or remote from sources of noise; in a hospital, it may be essential that certain departments are close together to deal with emergency cases. In such circumstances the systematic layout planning (SLP) method may be suitable. It will be illustrated by a simple example.

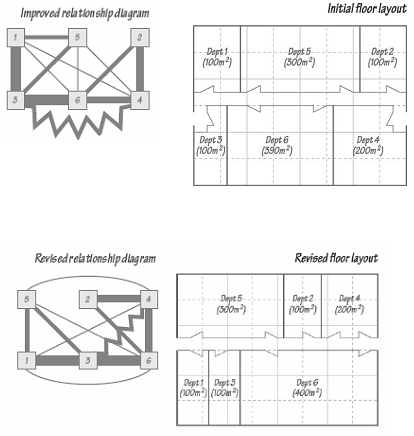

Six departments (1 - 6) are to be laid out on a single floor of a building, shown in the figure above. Making allowances for a 2m-wide corridor between the doors, the net area available for the departments is 1200m2. Having considered the needs of the departments, the allocations are as follows: 1 - 100m2, 2 - 100m2, 3 - 100m2, 4 - 200m2, 5 - 300m2, and 6 - 400m2.

The next step is to consider each pair of departments and make an assessment of the desirability of them being close to each other. A simple code, which employs the vowels and 'X', is used for rating, with the significance shown in the following table.

SLP rating codes

Code Meaning

A Absolutely necessary

E Essential

I Important

O Ordinary importance

U Unimportant

X Undesirable

The closeness ratings are presented in a grid, as in the figure above, the ratings being entered at the intersections of rows. For example, the pairing of departments 1 and 3 has the highest rating, 'A', whereas departments 3 and 4 must not be adjacent, 'X'.

The next step is to draw a relationship diagram, (see figure), which represents the ratings as lines of varying intensity. In this initial diagram the positions may be chosen arbitrarily. The diagram is then scrutinised with a view to amending it to bring the 'A' departments together, and separate the 'X' departments. This figure shows an amendment of the previous relationship diagram to achieve this. Although, in this simple case, a 'good' configuration has been achieved in one step, in more complex circumstances (eg more departments), several iterations may be required to obtain a satisfactory arrangement. We can now try to develop a floor plan, taking into account the space requirements of the departments and the constraints imposed by the building. The figure above shows one of many possible floor plans. A feature of this layout that may be deemed undesirable is the extra space taken up by the dog-legged corridor. In the light of this, further scrutiny of the relationship diagram allows another configuration, shown in these two figures, which might be considered better.