Resulting structure of steel:

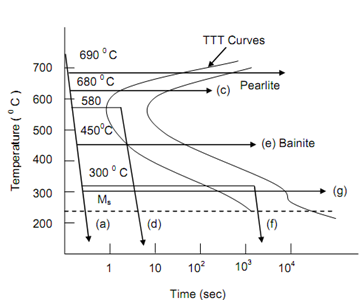

Heat treatments as mentioned below are given to thin steel strips for which TTT diagram is as shown in Figure 19. What will be the resulting structure of steel in each case.

Treatments

1. Water quench to room temperature.

2. Hot quench in molten salt to 690oC hold for 2 hours and water quench.

3. Hot quench to 610oC & hold 3 minutes, water quench.

4. Hot quench to 580oC, hold for 25 minutes, water quench

5. Hot quench to 450oC, hold for 1 hour, water quench

6. Hot quench to 300oC, hole for 30 minutes, water quench

7. Hot quench to 300oC, hold for 5 hours, water quench

Solution

From Figure 19 the final structures of steel can be determined

1. Martensite

2. Coarse pearlite

3. Fine pearlite

4. 50% fine pearlite and 50% martensite

5. Bainite

6. 50% fine bainite and 50% martensite

7. Fine bainite

Figure: Cooling Scheme of Example