RCC Pipe Culverts:

Reinforced cement concrete pipe culverts are ideal for dealing with small discharges. The advantages are :

(a) They are very economical, since a circular section is the most ideal for withstanding forces from all around.

(b) Since the pipes do not need very elaborate bedding, the cost further comes down.

(c) Pipe culverts do not demand structural design for individual cases. Pipes are standardised, in terms of mix, thickness and reinforcement.

(d) Pipes can be cast under strictly controlled conditions at a Central plant and thus their quality is assured.

The disadvantages with pipes are that they cannot be used for large openings. A minimum cover of at least half the diameter of the pipe is to be ensured over the pipes.

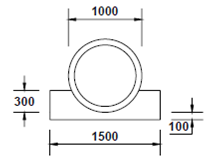

(a) Granular bedding (Figure), which consists of forming and grading the bed with sand or any granular material passing 4.75 mm sieve. The thickness of the bedding layer should be minimum 75 mm. Such bedding is suitable for fills upto 4 m height.

Figure: Granular Bedding for Pipe Culverts

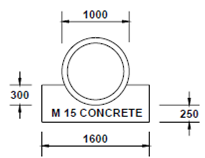

(b) Concrete cradle bedding (Figure 7), which consists of a concrete bed of M-15 grade concrete. The thickness of the bedding layer should be minimum 250 mm. Such bedding is used for height of fills above 4 m.

Figure: Concrete Cradle Bedding for Pipe Culverts

Single pipe or a row of pipes can be used. The distance between pipes should be at least half the diameter of the pipe subject to a minimum of 450 mm. the pipes are kept sufficiently below the floor of the deepest bed. Pipe culverts are generally designed to flow full. Suitable head-walls are needed to protect the embankment fills. The slope of the floor is kept to a minimum of 1 : 1000.