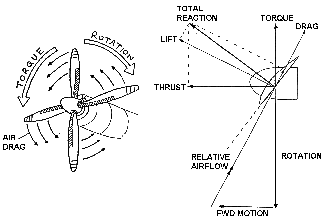

PROPELLER TORQUE

Propeller torque is produced by the aerodynamic drag on the blades when in motion. Propeller torque acts in the plane of rotation and opposes engine torque. When propeller torque and engine torque are equal the propeller will rotate at constant speed.

BLADE FORCES

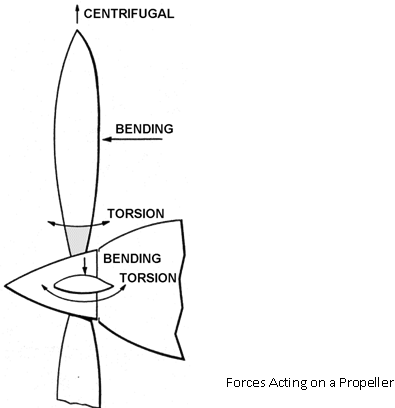

A propeller has to be capable of withstanding severe stresses that are greater near the hub and are caused by centrifugal forces and thrust. The force tending to through the blade from the hub is often as much as 22 tons. The stresses increase in proportion to the R.P.M. The blade face is also subjected to tension from the centrifugal force and additional tension from the bending. For these reasons, nicks or scratches on the blade can cause failure linked with stress corrosion.

BLADE RIGIDITY

A propeller must also be rigid enough to prevent flutter, a type of vibration in which the ends of the blade twist back and forth at high frequency around an axis perpendicular to the engine crankshaft. Flutter is often accompanied by a distinctive noise frequently mistaken for exhaust noise. The constant vibration tends to weaken the blade and may eventually cause failure.

FORCES ACTING ON PROPELLER BLADES

• Bending - Due to thrust and torque forces on the blade.

• Centrifugal - Caused by the propeller blade mass rotating at high speeds.

• Torsion - Due to the affects of CTM and ATM (see pages1-7 &1-8) and pitch change loads.

• Thrust is the component acting at right angles to the plane of rotation.

• Torque is the component acting in the plane of rotation opposing engine torque and is the resistance offered by the propeller to rotation.

Thrust and Torque values developed by the propeller depend on the angle of attack, the R.P.M. and air density. As air density increases so will thrust, but as increased resistance is felt by the propeller, torque will also increase. Thrust and torque will alter in direct proportion to propeller speed and any increase in the Angle of Attack (below stalling speed) will produce more thrust and torque. There is an optimum angle of attack for all propellers, usually about 40.

The aerodynamic of the propeller can most easily be understood if the action of the propeller is considered. The motion is both rotational and forward, and as far as the forces are concerned, the result is the same as if the blade were stationery and the air were coming at it from a direction opposite its path. The air deflection produced by this angle causes the dynamic pressure at the engine side of the propeller blade (the blade face) to be greater, thus producing thrust.