Propeller control :

CONSTANT SPEED UNIT:

In the normal flight range, the main control of the propeller is exercised by the propeller control unit (PCU).

MANUAL AND AUTOMATIC FEATHERING CONTROLS

All turbo-prop aircraft are fitted with some form of manual feathering control. In some cases this control is integral with the HP cock for the associated engine; in others the feathering control is operated through the fire protection system which also closes the HP cock. Automatic feathering control is fitted to many turbo-prop engines to avoid excessive drag following an engine failure. The automatic system receives signals from the engine torquemeters and reacts to unscheduled loss of torque by feathering the appropriate propeller. On twin-engine turbo-prop aircraft, the operation of the autofeather system on one engine automatically inhibits the same operation on the other engine, while still allowing the latter to be feathered manually.

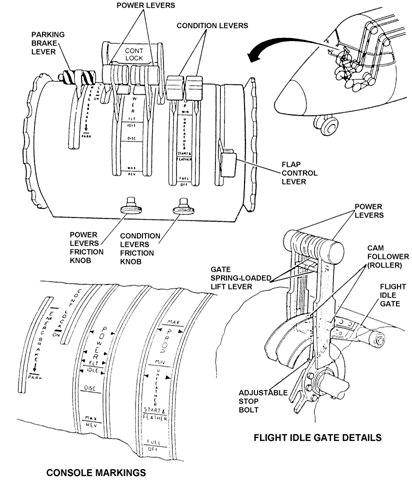

Power Lever

The power lever operates in a quadrant slot labelled "POWER" with positions (from rear to front) labelled "MAX REV", "DISC", "FLT IDLE" and "MAX". The power lever is connected by cables, pushrods and bellcranks to the control system and PCU of the associated powerplant. The power lever quadrant slot has a lockout gate at the FLT IDLE position, which is controlled by a finger latch below the power lever knob. Raising the latch permits aft movement into the ground range.

The power lever controls power in the forward thrust range and blade angle in the flight Beta and ground Beta ranges. The flight Beta range extends from a blade angle of 26° to 19 (minimum in-flight blade angle). The power lever controls blade angle from aft of FLT IDLE to MAX REV.

The spring-loaded, detented DISC position produces at 0 blade angle or flat discing; further aft movement increases blade angle in a negative direction until at MAX REV the blade angle is -11.5°. Both of these positions will assist in slowing the aircraft during landing.

While operating in the Beta range, the HP fuel control regulates engine power, providing Np underspeed governing between FLT IDLE and DISC and both engine power and blade angle control in the reverse thrust range.

When the flight control gust lock lever, labelled "CONT LOCK" is at the on position, the power lever cannot be moved to the MAX position. This lever will also lock the aircraft flight controls.