Formulate stress analysis techniques relevant to a range of situations.

The Brief

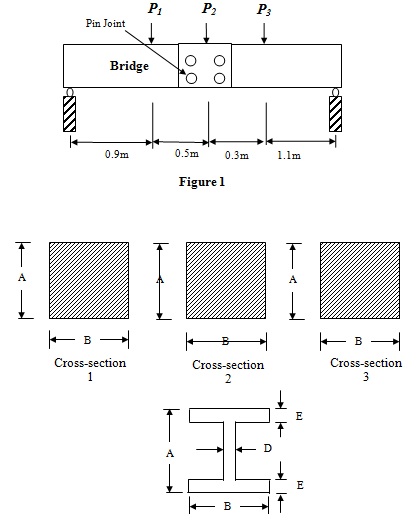

A company has come and seek your advice on their draft design flat bridge. The bridge will have several forces acting on its top surface as shown in figure 1. The material of the bridge is made from steel having a Young's modulus of E = 220000MPa, a Poisson's ratio of m = 0.28, and yielding stress of 650 MPa. There are four types of cross section are to be considered to be used by the company as shown in figure. The bridge will be connected to each other with the pin joint in the middle of the section.

The parameters for each of the three pipes are:

A = B = 0.3m, C = 0.15m, D = 0.02m, E = 0.05m , P1=18000N, P2=26000N, P3=20000N

a) Calculate and plot the stresses for each of the four sections for the above problem by using a 3-dimensional solid element type of finite element software.

b) Plot and list the maximum deflections for each cross section.

c) Calculate the safety factors for each pipe and discuss which type of cross section you would choose to use.

d) Hand Calculation MUST be used and compare with the result from the Simulation. A specific method MUST be used to conduct the hand calculation.

Due to the rearrangement of other components, the two supports have to be moved further apart and each force has to be halved. However, the middle force has to change due to circumstance to be uniform load distribution, as shown in Figure.