Find power transmitted by cross type belt:

Find power transmitted by cross type belt drive connecting two pulley of diameter 45.0cm and 20.0cm that are 1.95m apart. The maximum permissible tension in belt is 1KN, coefficient of friction is 0.20 and speed of the larger pulley is 100rpm.

Sol: Given that

D1 = Diameter of the driver = 45cm = 0.45m

R1 = Radius of the driver = 0.225m

D2 = Diameter of the driven = 20cm = 0.2m

R2 = Radius of the driven = 0.1m

X = Distance between the centers of two pulleys = 1.95m

T1 = Maximum permissible tension = 1000N

µ = Coefficient of friction = 0.20

N1 = Speed of the driver(Larger pulley) in R.P.M. = 100RPM

As we know that,

Power Transmitted = (T1-T2).V/1000 Kw ...(i)

Tension is in KN and V is in m/sec

First ve find the velocity of the belt, V = Velocity of the belt in m/sec.

Here take diameter and Rotation per minute of larger pulley

= pDN/60 m/sec, D is in meter and N is in Rotation per minute

= (3.14 X0.45 X 100) /60

= 2.36m/sec ...(ii)

Now Ratio of belt tension, T1/T2 = eµθ ...(iii)

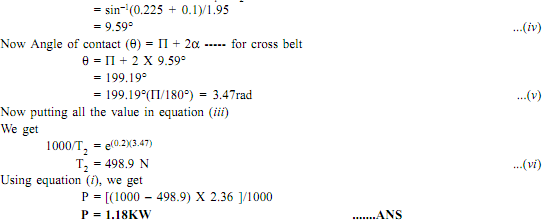

Here we do not know the value of θ, For θ, first find the value of a, then by formula,

Angle of Lap for cross belt a = sin-1(r1 + r2)/X