Evaluate the motion of the system:

If in above Example, the block A is resting on an inclined plane at 45o to horizontal as illustrative in Figure, find out the motion of the system assuming μ = 0.1.

Solution

Supposing that block A moves upwards a distance s while B moves downwards by (s/2) as before as shown in Figure

N A = WA cos 45o

= 400 × 0.707

= 283 N.

Friction = 0.1 × 283

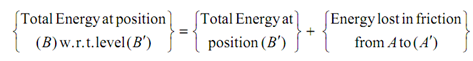

By using the principle of conservation of energy & letting datum level as B′ which is the final position of B,

WA (H + (s/2))+ WB× (s/2) = WA ( H + (s /2)+ s × sin α + (1/2)M A V 2 +(1/2)MB (V/2)2 + 28 × s

∴ 10 × g ( s/2) - 40 × 0.707 s - 28 × s = V 2 (40 +(10/4))

By using equation of motion of uniform acceleration a,

V 2 = 2 a s (since initial velocity is zero)

∴ approximately 49 - 28 - 28 = a (42.5)

∴ a = - 7 /42.5 m / sec2

Negative sign indicates that assumed direction of motion of A is not right and therefore the block A moves downward. As direction of friction also changes (that means upwards), the magnitude of acceleration is recomputed separately.

The system while A moves down through distance s, its velocity is V while Block B moves up with velocity (V/2) considering initial- position of Block B as datum level,

V 2 = 2 (a × s)

Where, a = acceleration of A,

WA (H) = W [H - s (sin α)] + WB (s/2) + 40(V2/2) + (10/2) (V2/4) + F × s

∴ 0 = - 40 × (s × 0.707) × 9.8 + 10 × (9.8 × s)/2 + (V2 /2) (42.5) + 28 s

∴ 0 = s [(- 280 + 49 + 28) + a × 42.5]

Taking 277.14 ≈ 280

∴ a = 203 /42.5

≈ 4.7 m / sec2.

Hence, Block A moves down with acceleration of 4.7 m/sec2.