Discover the fixing torques set up at the ends of the shaft:

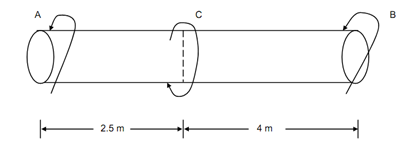

A solid shaft 6.5 m long is securely fixed at each of the end. A torque of 91 Nm is applied to the shaft at a section 2.5 m from one end as illustrated in Figure. Discover the fixing torques set up at the ends of the shaft.

Figure

If the shaft is equal of 35 mm diameter, discover the maximum shear stresses in two portions. Discover also the angle of twist for the section where the torque is applied.

Take G = 8.4 × 104 N/mm2.

Solution

Consider θ = angle of twist of C. k, k1, k2 mention the stiffness of the overall shaft and parts respectively AC and CB,.

l1 = 2.5 m

l2 = 4.0 m

k 1 = G1 J1 /l1 , k2 = G2 J 2/l2

J1 = J 2 = ( (P/ 32) × (35)4 = 1.47 × 10 5 mm4

k = 8.4 × 10 4 × 1.47 × 105/2.5 × 103

= 5 × 106 Nmm/rad

k = 8.4 × 10 4 × 1.47 × 105/4 × 103

= 3.1 × 106 Nmm/rad

∴ k = k1 + k2 = 8.1 × 106 Nmm/rad

T = 91 × 103 Nmm/rad, θ = T /k

q = ( 91/8.1 ) 10- 3 = 11.23 × 10- 3 rad = 38′ 36′

T1 = k1 θ = 5 × 106 × 11.23 × 10- 3 = 56.2 Nm

T2 = k2 θ = 3.1 × 106 × 11.23 × 10- 3 = 34.8 Nm

Check that T1 + T2 = 91 Nm

τ1 = 16T1 / π d 3= 16 × 56.2 × 10 -3/ π (35)3

= 6.7 N/mm2

τ1 = 16T1 / π d 3= 16 × 34.8 × 10 -3/ π (35)3

= 4.15 N/mm2