Determine Maximum fibre stress:

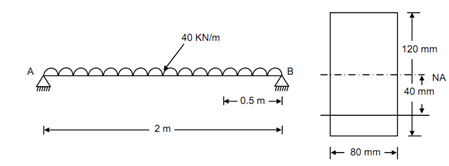

A beam of rectangular section of 80 mm to 120 mm carries a uniformly distributed load of 40 kN/m over a span of 2 m an axial compressive force of 10 kN. Determine

1. Maximum fibre stress,

2. Fibre stress at a point 0.50 m from the left end of the beam & 40 mm below the neutral axis.

(1) Loading (2) Cross-section

Figure

Solution

Bending moment, M = (w × e 2) /8= (40 × 22)/8 = 20 kN-m = 20 × 106 N-mm

Section modulus, Z = (1/6) × 80 × (120)2 = 1.92 × 105 mm3

Moment of inertial, I = (1/12) × (80) × (120)3 = 11.52 × 106 mm4

Axial load, P = 10 kN = 10 × 103 N

Direct stress, f0 = P/A =10 × 103/ (80 × 120) = 1.04 N/mm2

Bending stress, f b =± M/ Z =( 20 × 106 )/(1.92 × 105) = ± 104.16 N/mm2

∴ Maximum fibre stress = 1.04 + 104.16 = 105.20 N/mm2 (compressive)

∴ Bending moment at 0.50 m from left end will be,

M = ( - 40 × 0.50 + 40 × 0.502 / 2)

= - 15 kN-m

= 15 × 106 N-mm (sagging)

∴ Bending stress at 40 mm below the neutral axis will be,

= (M/I) . y

= (15 × 106 )/(11.52 × 106 ) × (- 40)

=- 52.08 N/mm2 (tensile)

∴ Resultant fibre stress = 1.04 - 52.08

=- 51.04 N/mm2 (tensile)