Reference no: EM131356597

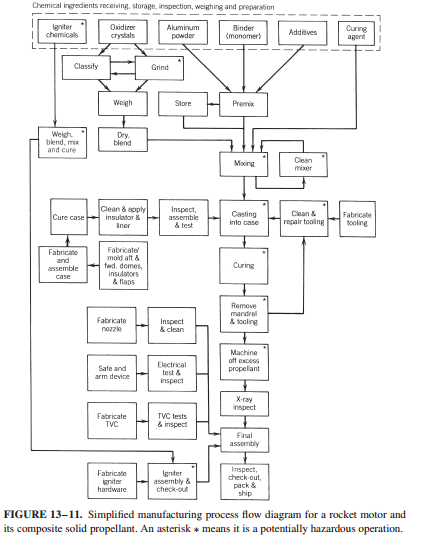

Prepare a detailed outline of a procedure to be followed by a crew operating a propellant mixer. This 1-m3 vertical solid propellant mixer has two rotating blades, a mixing bowl, a vacuum pump system to allow mix operations under vacuum, feed chutes or pipes with valves to supply the ingredients, and variable-speed electric motor drive, a provision for removing some propellant for laboratory samples, and a double-wall jacket around the mixing bowl to allow heating or cooling. It is known that the composite propellant properties are affected by mix time, small deviations from the exact composition, the temperature of the mix, the mechanical energy added by the blades, the blade speed, and the sequence in which the ingredients are added. It is also known that bad propellant would be produced if there are leaks that destroy the vacuum, if the bowl, mixing blades, feed chutes, and so on, are not clean but contain deposits of old propellant on their walls, if they are not mixed at 80? C, or if the viscosity of the mix becomes excessive. The sequence of loading ingredients shall be: (1) prepolymer binder, (2) plasticizer, (3) minor liquid additives, (4) solid consisting of first powdered aluminum and thereafter mixed bimodal AP crystals, and (5) finally the polymerizing agent or crosslinker. Refer to Fig. 13-11. Samples of the final liquid mix are taken to check viscosity and density. Please list all the sequential steps that the crew should undertake before, during, and after the mixing operation. If it is desired to control to a specific parameter (weight, duration, etc.), that fact should be stated; however, the specific data of ingredient mass, time, power, temperature, and so on, can be left blank. Mention all instruments (e.g., thermometers, wattmeter, etc.) that the crew should have and identify those that they must monitor closely. Assume that all ingredients were found to be of the desired composition, purity, and quality.

|

Prefers borrowing at floating rate while non-financial firm

: Bank A prefers borrowing at a floating rate while a non-financial firm prefers borrowing at a fixed rate. However, the fixed and floating rate facing the bank is 3% and 3-month LIBOR plus 8 basis points, respectively, while the fixed and the floating..

|

|

Molding machine to be used in its manufacturing process

: The XYZ Company needs to acquire a molding machine to be used in its manufacturing process. Two types of machines that would be appropriate are presently on the market. Determine which machine XYZ should purchase. Assume an interest rate of 8% proper..

|

|

Why you feel it is important to have historical perspective

: Explain why you feel it is or is not important to have a historical perspective of management, Can you think of ways it may help or hinder us today?

|

|

Maintain inventory master data

: Maintain inventory master data.- Record newly arrived shipments of inventory.- Record returns of incorrect or damaged inventory.

|

|

Prepare a detailed outline of a procedure to be followed

: Mention all instruments (e.g., thermometers, wattmeter, etc.) that the crew should have and identify those that they must monitor closely. Assume that all ingredients were found to be of the desired composition, purity, and quality.

|

|

Identify an advertisement that targets generational groups

: BUSI 330-D09: Identify an advertisement or commercial that targets only one of the generational groups. Describe the promotion in detail and identify the intended group.

|

|

Difference between state and federal anti-discrimination law

: Project will be a comparison/contrast paper that explores the difference between state and federal anti-discrimination laws in the workplace - describe and explain any areas where it appears that the state's employment discrimination laws cover are..

|

|

Does marketing have a function in church operations

: Define marketing and sales and explain how they are different from one another. How are they dependent upon one another? Does marketing have a function in church operations? Explain and support this.

|

|

Choose two air pollutants from the list and generate report

: Investigate the hazardous chemicals in your area. After choosing your area from the map, choose Monitor Values under Hazardous Air Pollutants. Choose two air pollutants from the list, and generate your report. Tell the class which chemicals you cho..

|