Dihydrogen chemistry

H2 is mostly produced through steam re-forming of hydrocarbons. The very simple reaction is

In this endothermic reaction, the equilibrium is focused to the right by make use of elevated temperatures (900°C). The general catalyst is Ni hold up on Al2O3. The H2-CO mixture is termed as synthesis gas or syngas, and might be used directly for additional reactions, the very significant being methanol synthesis:

CO+2H2 → CH3OH

A Cu-ZnO-Al2O3 catalyst is employed, that is less active than ones including metals in earlier groups, that's why the C-O bond is not broken. Methanol is a significant stage in further synthesis; for instance, the Monsanto acetic acid process catalyzed through Rh compounds.

Other significant reaction for synthesizing helpful organic compounds is hydroformylation:

RCH = CH2 + CO + H2→ RCH2CH2CHO

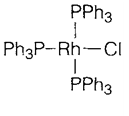

Homogeneous catalysts derived from cobalt carbonyl compounds were used before, but have been largely substituted through the Union-Carbide process along with [(Ph3P)2Rh(CO)Cl] like the catalyst.

Two main uses of H2 are for the hydrogenation and ammonia synthesis of unsaturated vegetable oils to compose margarine. The previous reaction is exothermic and the equilibrium constant so reduces along with temperature. A potassium-promoted iron catalyst is employed In the Haber process, this comparatively reactive metal being essential to adsorb and dissociate the extremely stable N2 molecule at moderate temperatures (400°C). The yield of NH3 is enhanced through working at high pressure. Large-scale catalytic hydrogenation of the alkenes is generally performed with a Ni-SiO2 catalyst. More selective hydrogenation for particular purposes (example pharmaceuticals in which particular isomers are needed) is possible with homogeneous catalysts; for instance, Wilkinson's catalyst (2), that goes through oxidative addition of H2 under mild circumstances.