Preparing and Placing of Concrete

Steps are involved in the concreting are following:

- Batching

- Mixing

- Transporting and placing and

- Compacting.

1. Batching: for making concrete the measurement of materials is known as batching. Two methods of batching are following:

1. Volume batching

2. Weight batching.

(a) Volume Batching: sand and concrete are batched by volume in this method cement. With wooden plates a gauge box is made, its volume being equal to that of one bag of cement. One specific bag of cement has volume of 35 litres. By measuring on to the gauge box the required amount of sand and coarse aggregate is added. After deciding water cement ratio the quantity of water required for making concrete is found. For instance, if, for one bag of cement (50 kg) water cement ratio is 0.5, water required is 0.5 × 50 = 25 kg, which is equal to 25 litres. Suitable measure is used to choose required quantity of water. Volume batching is not perfect method of batching. For the same weight of dry sand Wet sand has higher volume. It is called as bulking of sand. Therefore it upsets the calculated volume which is required.

(b) Weight Batching: This is the suggested method of batching. In the field a weighing platform is used to pick up accurate proportion of sand and coarse aggregates. Large weigh batching plants is having automatic weighing equipments.

2. Mixing: it is necessary to mix cement to produce uniform and good concrete, sand and coarse aggregate, first in dry condition and then after adding water in wet condition .methods of practiced is following:

- Hand Mixing

- Machine Mixing.

(a) Hand Mixing: for a batch required amount of coarse aggregate is weighed and is spread on an impervious platform. Then for the batch the sand required is spread over coarse aggregate. By overturning the mix they are mixed in dry condition with shovels. Then for the batch the cement is required, which is spread over the dry mix and mixed by shovels. After uniform texture is observed water is added slowly and mixing is continued. When uniform colour and consistency is observed, Full amount of water is added and mixing is completed. The procedure of mixing is completed in 6-8 minutes of adding water. This method of mixing is not so good but for small works it is normally adopted.

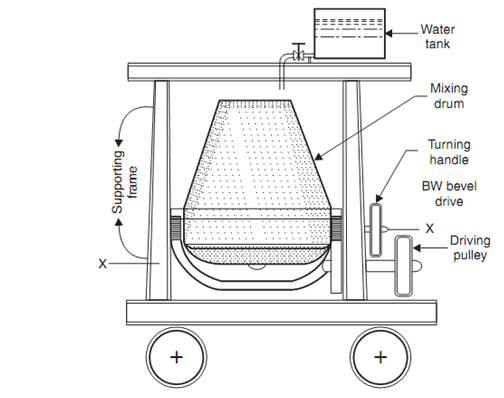

(b) Machine Mixing: mixing is preferred in large and important works machine. Given figure shows a typical concrete mixer. If sand and coarse aggregates required quantities are placed in the drum of the mixer. For dry mixing, Four to five rotations are made and then required quantity of cement is added and with another 4 to 5 rotations, dry mixing is made. Water is steadily added and drum is rotated for 2 to 3 minutes during which period it makes approximate 50 rotations. Uniform and homogeneous mix is obtained at this stage.

Concrete mixer

3. Transporting and Placing of Concrete. Concrete should be transported after mixing to the final position. In iron pans, it is transported from hand to hand of a set of workers in small works. Hand carts and Wheel barrow also may be employed. Concreting chutes and belt conveyors or pipes with pumps are employed in large scale. In transporting care should be taken to see that segregation of aggregate from matrix of cement do not occurs.

Concrete is placed on form works. The form works should be properly oiled and cleaned. The soil bed should be compacted If concrete is to be placed for foundation, well and It is made free from loose soil.

If concrete is to be placed for foundation, Concrete should be dropped If concrete is to be placed for foundation, as closely as possible. the coarse aggregates fall early and then mortar matrix If it is dropped from a height. This segregation results into weaker concrete.

4. Compaction of Concrete: Air is entrapped in the process of placing concrete. The entrapped air reduces the strength of concrete up to 30 percent. Therefore it is necessary to remove this entrapped air. This is achieved after placing it in its final position, by compact the concrete. Compaction can be performed either by hand or with the help of vibrators.

(a) Hand Compaction: concrete is compacted by, tamping, ramming, spading or by slicing with tools in this method. a pointed steel rod of 16 mm diameter and about a metre long is used In intricate portions for poking the concrete.

(b) Compaction by Vibrators: by using high frequency vibrators, Concrete can be compacted .Vibration reduces the friction between the particles and set the motion of particles. Entrapped air is removed as a result and the concrete is compacted. The compaction time is reduces by use of vibrators. For compaction when vibrators are used, water cement ratio can be less, which can also help in improving the strength of concrete as soon as cement paste is seen on the surface of concrete vibration should be stopped. For the concrete over vibration is not good.

Types of vibrators which are commonly used in concreting are following:

- Needle or immersion vibrators

- Surface vibrators

- Form or shutter vibrators

- Vibrating tables.

In concreting beams and columns, Needle vibrators are used. And In concreting slabs Surface vibrators and form vibrators are useful. In preparing precast concrete elements, Vibrating tables are useful Curing of Concrete

As the process of maintaining satisfactory moisture and temperature conditions, Curing can be defined for freshly placed concrete for proper hardening of concrete for some specified time. In the early ages of concrete Curing is more important. Curing for 14 days is very essential. Better to continue it for 7 to 14 days more. If curing is not done correctly, the strength of concrete will be reduces. Due to shrinkage, Cracks develop. Durability of concrete structure reduces.

Curing methods which are employed described below:

- Spraying of water

- Covering the surface with wet gunny bags, straw etc.

- Ponding

- Steam curing and

- Application of curing compounds.

(a) Spraying of water: by sprinkling water the columns, Walls, plastered surfaces are cured.

(b) Wet covering the surface: with wet gunny bags or straw Columns and other vertical surfaces may be cured by covering the surfaces.

(c) Ponding: By stagnate the water, the horizontal surfaces such as slab and floors are cured to a height of 25 to 50 mm with mortar by providing temporary small hunds.

(d) Steam curing: units steam is passed over the units kept in the manufacture of pre-fabricated concrete in closed chambers. Resulting into the reduction of curing period it accelerates curing process,

(e) Application of curing compounds: on the curing surface Compounds such as calcium chloride may be applied. Compound shows affinity to the moisture and received it on the surface. It remains the concrete surface wet for a long time.