Operational Issues in Tool Engineering

The distinct kinds of operations carry out by a cutting tool are given as follows:

Facing

Facing is carried out on lathe machine. Facing produce flat surface, normal to the axis of rotation by feeding the tool from the surface towards the centre or outward from the centre. In facing operation, the depth of cut is measured in direction parallel to the axis and feed in a radial direction. In this operation the cutting speed continuously varies, that means approaching zero towards the centre of the bar.

Turning

Turning is also performed on lathe.

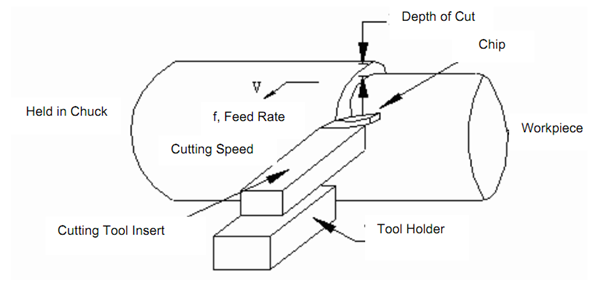

Figure: Lathe Turning

The tool is held rigidly in a tool post and moved at a constant rate along the axis of the bar, cutting away the layer of material to form a cylinder or a surface of more complex profile. Figure illustrates principle of turning operation.