Maximum shear stress and angle of twist:

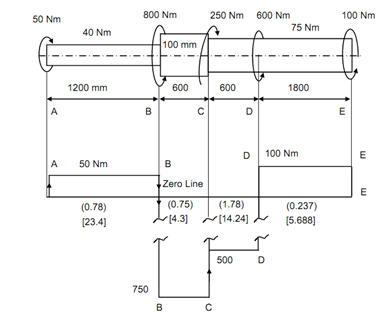

Torques are applied on the shaft as illustrated in Figure. Discover in which portion of the shaft, maximum shear stress & angle of twist takes place.

Figure: Torque Diagram

Solution

Torque diagram is drawn below the shaft. For the cause a zero line is selected and clockwise torque is plotted above this line, that means upward and anticlockwise torque is plotted downward.

At A raise 50 Nm up, A to B the constant torque and 800 Nm down. Thus at section B

the torque TB = 800 - 50 = 750 Nm  From B to C constant torque and at C,

From B to C constant torque and at C,

TC = 750 - 250 = 500 Nm From C to D torque is constant and at D,

From C to D torque is constant and at D,

TD = 600 - 500 = 100 Nm At E the torque is 100 -100 = 0. Therefore, highest torque acts on portion BC and TB = 750 Nm. For discover maximum stressed T/ d 3 portion check for . These values are written on torque diagram below zero line.

At E the torque is 100 -100 = 0. Therefore, highest torque acts on portion BC and TB = 750 Nm. For discover maximum stressed T/ d 3 portion check for . These values are written on torque diagram below zero line.

By Verifying the highest stress shall occur in portion CD.

τm = 16TC / π d 3 = 16 × 500 × 103/ π (75)3

= 6.036 N/mm2

The largest angle of twist is decided by largest value of Tl/ J or Tl/ d 4 . These values are written below the values of T/d3 on torque diagram.

The largest twist occurs in portion AB.

θ max = TA l / J G

=50 × 103 × 1200/ (π/32) (40)4 × 80 × 103

= 2.984 × 10- 3 rad = 0.171 deg.

= 10′ 15.5′′ C.