Engine protection devices :

Described below are typical protection devices that will override any excessive demands made on the engine by the pilot or by the control units.

TOP TEMPERATURE LIMITER.

Turbine gas temperature is measured by thermocouples in the jet pipe. When maximum temperature is reached, these pass a signal to an amplifier, which limits pump stroke by reducing pump servo pressure or moves the throttle valve in series with the pilot.

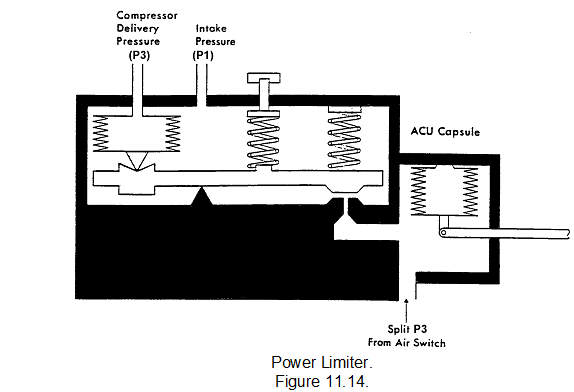

POWER LIMITER.

A power limiter is fitted to some engines to prevent over-stressing due to excessive compressor outlet pressure during high-speed, low altitude running. The limiter (see figure) takes the form of a half-ball valve which is opened against a spring force when compressor outlet press (P3) reaches its maximum value. The half-ball valve bleeds off air pressure to the ACU control capsule, thus causing the ACU to reduce pump stroke.

OVERSPEED GOVERNOR.

The engine is protected against over-speeding by a governor, which, in hydro-mechanical systems, is usually fitted on the fuel pump and acts by bleeding off pump servo fuel when the governed speed is reached. On two-spool engines, the pump is driven from the HP shaft and the LP shaft is protected by either a mechanical governor or an electro-mechanical device, again acting through the hydro-mechanical control system. There are two types of pump-driven governors:

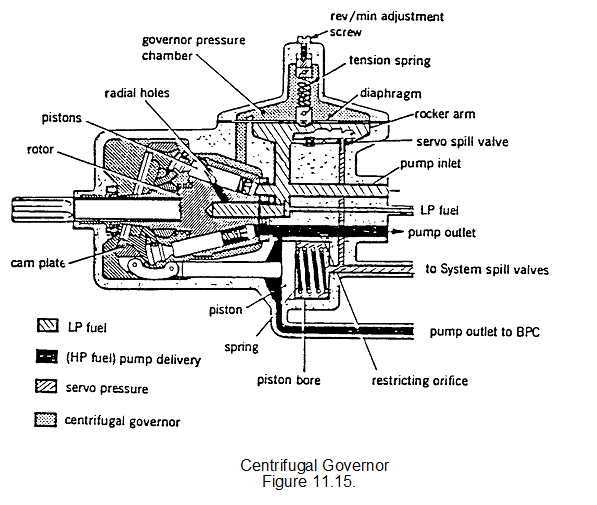

Centrifugal Governor.

The centrifugal type of governor uses the centrifugal pressure of fuel in radial drillings in the fuel pump rotor to deflect a diaphragm at maximum speed. The diaphragm operates on a half-ball valve to reduce pump servo pressure and thus pump stroke. The disadvantage of this type is that it needs to be reset if fuel specific gravity changes. It is seldom used on modern engines.

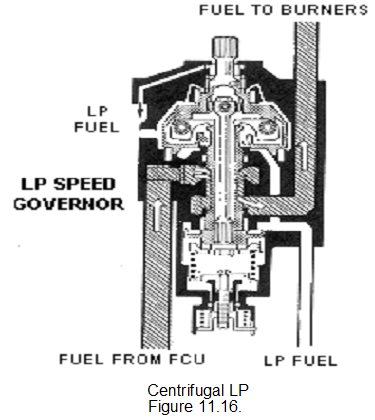

Centrifugal governors using bob weights are used as LP shaft governors on some engines. They will return fuel to low pressure when the LP shaft overspeeds see figure.

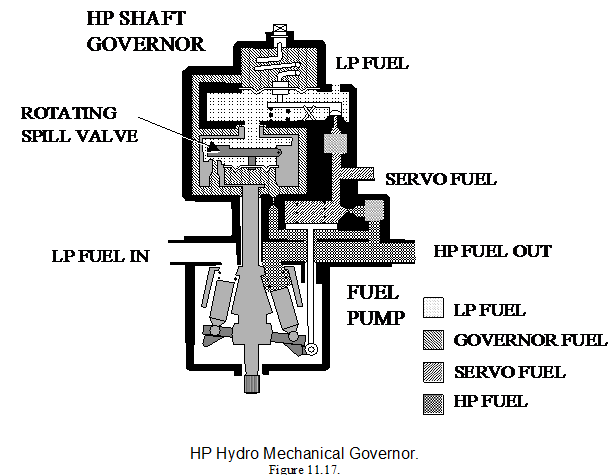

Hydro-mechanical Governor.

In the hydro-mechanical governor the pump drive shaft rotates a rotor containing a half-ball valve on a lever arm (shown in the figure). As engine speed increases, centrifugal force closes the valve, increasing the pressure of fuel in the governor housing (governor pressure) by restricting its flow to LP. When the maximum speed is reached, governor pressure is high enough to deflect a diaphragm, which opens the half-ball valve acting on pump servo. A hydro-mechanical governor does not require adjustment for changes in fuel specific gravity.