Calculate the maximum and minimum stress:

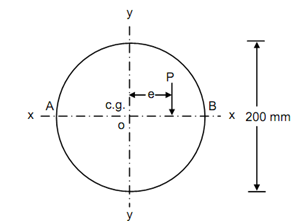

A cast iron column of 200 mm diameter carries a vertical load of 400 kN, at a distance of 50 mm from the centre. Calculate the maximum & minimum stress developed in the section, along with the diameter passing through the point of loading.

(a)

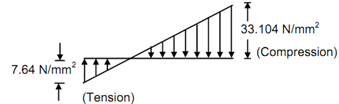

(b) Stress Distribution along the Diagonal

Figure

Solution

Vertical load, P = 400 kN = 400 × 103 N

Diameter of the section, D = 200 mm

Area of the section, A = (π/4) (200)2 = 31416 mm2

Direct stress, f0 =(P/A) =4 × 105/31416 = 12.732 N/mm2

Eccentricity, e = 40 mm

Bending moment, M = P × e = (400 × 103 ) 40 = 16 × 106 N-mm

Section modulus, z = π D 3/32 = π (200)3 /32= 785.4 × 103 mm3

Bending stress, f =± Pe / Z =± 16 × 106 /785.4 × 103=± 20.372 N/mm2

∴ Resultant stress at the edge, B = f0 + fb = 12.732 - 20.372

= 33.104 N/mm2 (compressive)

∴ Resultant stress at the edge, A = f0 - fb = 12.732 - 20.372

=- 7.640 N/mm2 (tensile)

The stress distribution along with the diameter is as illustrated in Figure (b).