Reference no: EM133050576

MP2714 Computer Aided Design and Simulation

Assignment 1 - Centrifugal Clutch Design

The aim of this assignment is to use industrial CAD systems to solve an engineering design problem.

Figure 1 Centrifugal Clutch

Usinga range of CAD and Simulation toolsyou are to design a Centrifugal Clutch. The assessment will be based on a Design Report highlighting your design work and use of CAD to solve an engineering problem.

The report will contain the following elements:

• Analysing Hardware requirements for CAD

• 3D CAD Modelling

• 2D Drawings for Manufacture

• FEA Analysis of a Clutch Shoe

• Motion Analysis of the Clutch

This is an individual assignment; you are to design a suitable centrifugal clutch to match a specific engine. An engine specification will be given to you and will be different for each student.

Learning Outcome 1: Analyse and compare the hardware requirements of different CAD systems. Identify and distinguish between the different types of CAD software: 2D draughting, 3D modelling (wire-frame, surface, solid), and other relevant systems

Learning Outcome 2: Use industrial standard CAD systems to produce the following: 3D CAD models, 2D engineering drawings.

Learning Outcome 3: Use industrial standard CAD and FEA systems to solve engineering design problems.

Learning Outcome 4: Analyse and model engineering situations using ordinary differential equations and solve ODEs.

Learning Outcome 5: Solve mathematical models of physical systems using simulation methods.

Technical Requirements

• The clutch must be designed to fit the Power-Take-Off shaft (PTO).

• The clutch must not engage when the engine is at idle (below 1500 rpm unless stated otherwise in the engine specification)

• The engagement of the clutch should be gradual from just above idle rpm up to the rpm at the start of the recommended operating speed range of the engine

• Clutch should remain engaged over the full operating speed range of the engine

• Clutch must not slip at peak torque.

• Drive from the clutch must be a single sprocket to take astandard roller chain suitable for the Horsepower and max rpm of the engine.

Engine Specifications

An engine specification will be given to you from the range of small Honda Engines. (do not choose your own)The Honda GX GC or GS engine range is a popular range of engines for a wide range of applications and it is common to use Centrifugal Clutches on these engines.

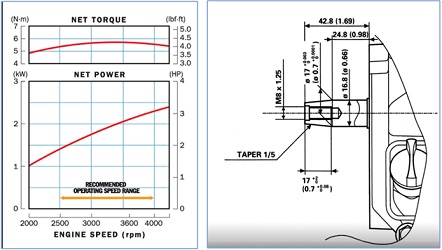

Each engine specification contains Performance Curves for information on Power, Torque and Engine Speed (rpm) as well as Technical Drawings of the PTO shaft. (Power Take-off shaft). Samples are shown below - Note: your engine specification may be different to these.

Sample Performance Curves Sample Drawing of a PTO Shaft

Design Report

You will be assessed via a Design Report. The report should be a 2000 word, liberally illustrated Technical Report. Most of the content is expected to be detailed Screen Shots/Imagesof your design. Graphical Results of your Motion Simulations are also expected. The report should also include initial design concepts and calculations related to the design.

It should be written in 3rd person, past tense with a logical numbered Chapter system. Research used for Part 1 should be correctly referenced.

Report Structure:

1. Analyse and compare the hardware requirements of different CAD systems. Identify and distinguish between the different types of CAD software: 2D draughting, 3D modelling (wire-frame, surface, solid), and other relevant systems

(a) Research typical CAD/PC systems used currently in industry. Consider PC / Hardware requirements for different CAD systems (include Processor/s, Monitors, Graphics Cards, Digitisers, RAM, Print/Plot devices). Describe how these might be configured in a typical Design Office.

(b) Show examples of the different types of CAD used in industry, include examples of 2D Drawing, 3D Solid Modelling, 3D Wire-Frame/Surface Modelling and any other relevant systems. Do not include vendor names of software i.e. SolidWorks, Catia, AutoCAD. Focus on the different types of CAD software that is available.

2. Use industrial standard CAD systems to produce the following: 3D CAD models, 2D engineering drawings.

With appropriate Screenshots and Descriptions show 3D Models and 2D Drawings of your design with descriptions to

(a) 3D CAD Part Models of Clutch Design

(b) 3D Assembly of Clutch Design

(c) 2D Detail Drawings of parts to be Manufactured i.e. Drum, Shoes, Backplate etc. (do not include standard parts i.e. nuts, bolts, springs, fasteners etc.)

3. Use industrial standard CAD and FEA systems to solve engineering design problems.

(a) Initial design calculations to predict behaviour of clutch design and establish boundary conditions.

(b) FEA Simulation of Clutch Shoe under maximum load conditions

(c) Motion Analysis of Clutch to show engagement.

Attachment:- Centrifugal Clutch Design.rar