Bearing Materials

Bearing is an extremely essential part of machines and materials utilized for bearings assume great significance. Generally this can be said that a good bearing material should possess given characteristics as:

(a) This should be strong sufficient to sustain bearing load,

(b) This should not heat rapidly,

(c) This should explain a small coefficient of friction,

(d) This should wear less, having long service life,

(e) This should work in foundry.

Usually it is expected that the journal and bearing would be made of dissimilar materials though there are illustrations where similar materials for journals and bearings have been utilized. When the two parts are made in the similar material the friction and when the wear are high.

Cast iron has been utilized as bearing material along with steel shafts in some conditions. Conversely, the various non-ferrous bearing alloys are now being utilized largely as bearing materials since they satisfy the conditions outlined over more satisfactorily.Bronzes, babbitts and copper-lead alloys are the significant bearing materials that are broadly used in service. A specific copper zinc alloy that is brasses, have been utilized as bearing materials, but only to limited extent. Because brass generally is cheaper, this has replaced bronze in some light duty bearings.

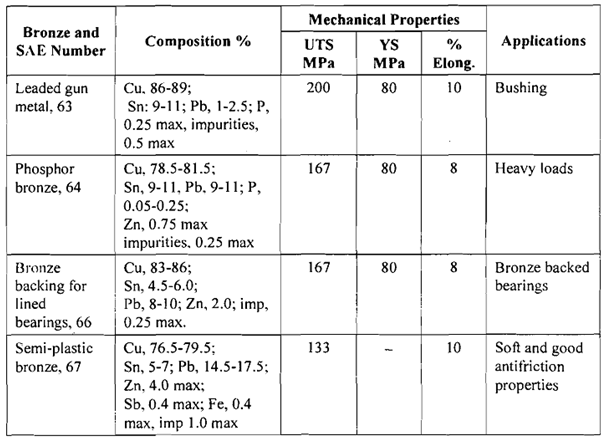

In given table describes several bearing bronzes:

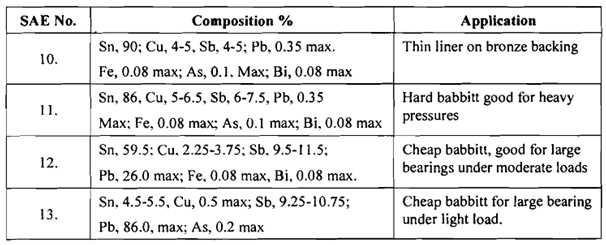

Table of Babbitt or White-bearing Metals

Copper-lead alloys, having a larger percentage of lead have determined a considerable utilize as bearing material lately. Straight copper-lead alloys of this type contain only half the strength of regular bearing bronzes. They are mostly advantageous over babbitt at high temperature like they can retain their tensile strength at that temperatures. The largest part babbitt have low melting point and lose almost at tensile strength at about 200°C. Usual copper-lead alloys contain about 75% copper and 25% lead and melt at 980°C. The room temperature tensile strength of copper-lead alloy is about to 73 Mpa and decreased to about 33 Mpa at about 200°C.