Sewer Construction

Prior to taking up the work of sewer construction, engineering drawings and specifications for the whole sewer system should be in place. In sewer construction work, two operations are of special importance, namely, excavation of trenches, and lying of sewer pipes in trenches and tunnels. Most of the trench work involves open cut excavation; and in urban areas it includes:

- Removing pavement,

- Removal of the material from the ground, and its separation, its classification where necessary, and its final disposal,

- Sheeting and bracing the sides of the trench,

- Removal of water (if any) from the trench,

- Protection of other structures, both underground and on the surface, whose foundations may be affected,

- Backfilling, and

- Replacement of the pavement.

The most common type of sewer construction practice involves the use of open trenches and prefabricated pipes. However, for larger sewer systems, and unusual situations may require tunnelling, jacking of pipes through the soil, microtunnelling or cast-in-situ concrete sewers.

On all excavation work, safety precautions for the protection of life and property are essential; and measures to avoid too great inconveniences to the public are desirable. Such measures and precautions include the erection and maintenance of signs (to forewarn public), barricades, bridges and detours; the placing and maintenance of lights both for illumination and also as danger signals; provision of watchmen to exclude unauthorized persons, particularly children from trespassing on the work; and such other precautions as local conditions may dictate. In addition, additional requirements are as follows:

(a) Each pipe section should be un-cracked.

(b) Proper placement (i.e., bedding) has to be there for each pipe section that is laid.

(c) There should be proper joining of pipe sections.

(d) There should be proper alignment (direction and longitudinal slope) of the line.

(e) Pipes should be covered properly with clean fill material (backfilled).

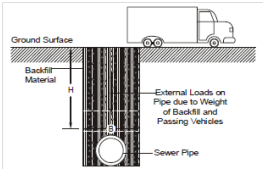

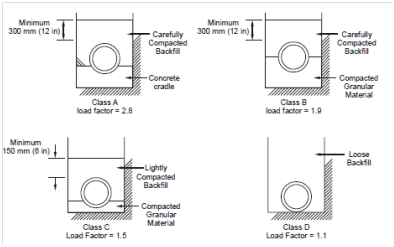

It is but obvious, that sewers have to be sturdy enough to sustain the load of the backfill material (dead load) laid over them, as well as the load due to the vehicular traffic (live load) to which it is subjected to (Figure 14). Factors like depth of the backfill, type of this material, and width of the trench influence the magnitude of the dead load; while the parameters that determine the load carrying capacity of the sewer line are the crushing strength of the pipe, and the characteristics of the pipe bedding (Figure 15). Bedding defines the way in which a pipe is placed on the bottom of the trench. Proper bedding distributes the load over the circumference of the pipe, and this increases the supporting strength of the pipe. The ratio of actual field supporting strength to the crushing strength of the pipe is known as load factor.

Figure 14: Loads Coming onto Buried Sewer

Figure 15: Different Types of Pipe Bedding

With reference to Figure 15, it may be pointed out that class D bedding is the weakest of all, and hence is not generally adopted. Here, the trench bed being left flat and bare, the pipe is not fully supported due to its projecting bell-ends. Further, if the backfill is placed loosely over the sewer without the necessary compaction, the bedding may not properly support the barrel. The ordinary bedding (Class C), offers a better support, say, with a load factor of 1.5. In first class bedding (Class B), the granular material extends halfway up the pipe, and a carefully compacted backfill can give a load factor of even 1.9. In Class A bedding, the barrel is supported by a concrete bed (yielding a load factor of 2.8) with a careful compaction of the backfill. It is common, in such engineering constructions, to define a safety factor (SF) as well, such as:

Safety Factor = Field Supporting Strength/Safe Supporting Strength

An SF of 1.5 is normally adopted for clay or unreinforced concrete sewers to address the possibility of using poor quality materials or for faulty construction. With a view to select the best bedding condition, it is to be ensured that the safe supporting strength is equal to or greater than the total expected load over the pipe.

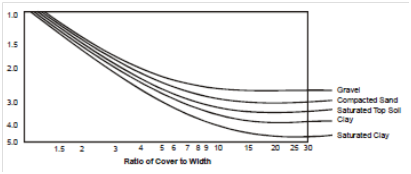

For pipelines situated in shallower trenches (such as, storm sewers or even some water mains) the component of load due to vehicular traffic may be a substantial part of the total load on the line. However, for deeper trenches (such as, sanitary sewers), the proportion of live load may not be significant compared to the dead load. In USA, Marston's Formula is commonly used to determine the load due to backfill, and is expressed as follows:

W = C w B2

where, W = Dead load due to backfill (kN/m),

C = A dimensionless coefficient,

w = Unit weight of the backfill soil (kN/m3), and

B = Width of the trench at the crown of the pipe (m).

In the equation, the value of C is to be selected depending upon the depth of backfill cover (H), width of the trench, and the type of backfill material (Figure 16).

Figure 16: Values of C in Marston’s Formula