PROPELLER SHAFTS

Most modern engines, both reciprocating and turbine, have flanged propeller shafts. Some of these flanges have integral internally threaded bushings that fit into counterbores in the rear of the propeller hub around each bolt hole. Propellers with these bushings are attached to the shaft with long bolts that pass through the propeller. On others the flange has a ring of holes and bolts pass from the engine side into threads in the propeller.

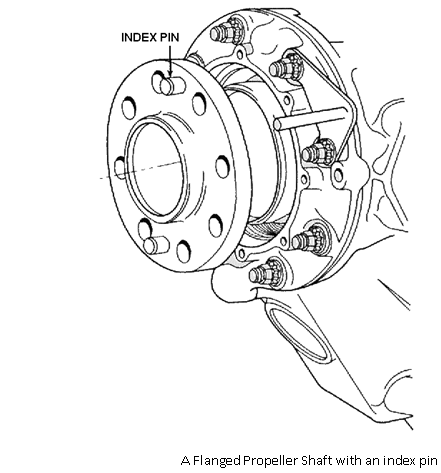

Some flanges have index pins in the propeller flange so the propeller can be installed in only one position relative to the shaft this done for synchronising and/or synchrophasing.

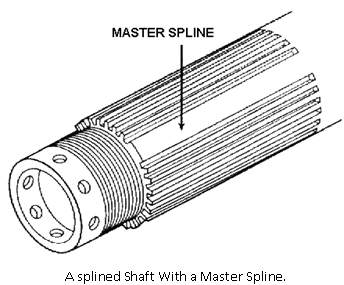

The most popular type of propeller shaft on reciprocating engines built through World War II and on the larger turboprop engines is the splined shaft. The sizes of splined shafts are identified by an SAE (Society of Automotive Engineers) number, SAE 20 splines are used on engines in the 200-horsepowered range; SAE 30 splines are used in the 300- and 400-horsepowered range, and SAE 40 in the 500- and 600-horsepowered range. SAE 50 in the 1,000-horsepowered range and SAE 60 and 70 are used for larger engines.

Splines are longitudinal grooves cut in the periphery of the shaft. The grooves and lands (the space between the grooves, are the same size, and one groove is either missing or has a screw in it to form a master spine. The purpose of the master spline is the same as the index pin.

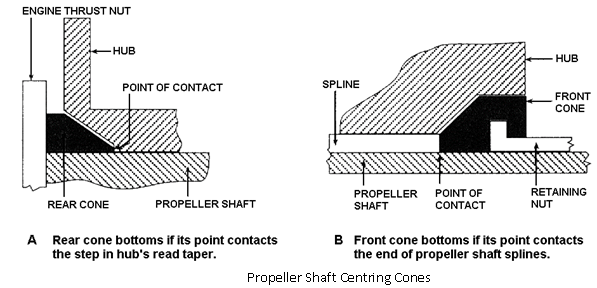

The inside of the propeller hub is splined to match the shaft and the hub is centred on the shaft with two cones. The rear cone is a single-piece split bronze cone, and is considered to be part of the engine. The front is a two piece hardened steel cone and is considered to be part of the propeller. The two halves are marked with the same serial number to ensure that only a match set is used. Prior to attaching a this type of propeller, a check is carried out to ensure correct contact of the cones. Engineers blue is applied to the cones and the propeller is fitted and torqued up, the propeller is then removed and there should be an even 80% contact around the cone on the propeller as seen by the blue, if there is not the cone can be stoned to fit, or replaced.