Problems on Cantilever Truss:

In the case of cantilever trusses, it is not required to determine the support reactions. The forces in members of cantilever truss are obtained by begning the calculations from free end of cantilever.

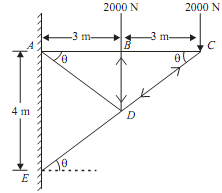

Q Determine forces in all the member of cantilever truss shown in the figure given below

Sol.: From ?ACE, we have

tan θ = AE/AC = 4/6 = 0.66 ...(i)

Also,

cos θ = AC/EC = 6/7.21 = 0.8321 ... (iii)

sin θ = AE/CE = 4/7.21 = 0.5548

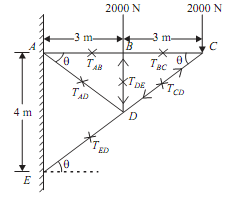

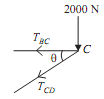

Joint C:

Consider free body diagram of joint C as shown in the given figure;

As the three forces are acting, so apply lami's theorem at the joint C.

TBC/sin(90 - θ) = TCD/sin270 = 2000/sin θ

TBC/cos θ = TCD/sin 270 = 2000/sin θ

TBC = 2000/tan θ = 2000/0.66 = 3000.3N ...(v)

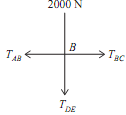

Joint B:

TBC = 3000.3N (Tensile) .......ANS

TCD = - 2000/sin θ = 2000/0.55 = 3604.9N ...(vi)

TCD = 3604.9N (Compressive) .......ANS

Consider free body diagram of joint B as shown in the given figure

As, TBC = 3000.3N

Let, TAB = Force in the member AB

TDB = Force in member DB

As the four forces are acting at the joint B, So apply resolution of forces at joint B

RH = TAB - TBC = 0, TAB = TBC = 3000.03 = TAB

TAB = 3000.03 ...(vii)

TAB = 3000.03N (Tensile) .......ANS

RV = - TDB - 2000 = 0

TDB = -2000N ...(viii)

TDB = 2000N (compressive) .......ANS

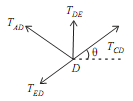

Joint D:

Consider free body diagram of joint D as shown in figure given below

As, TDB = - 2000N

TCD = 3604.9N

Let, TAD = Force in member AD

TDE = Force in member DE

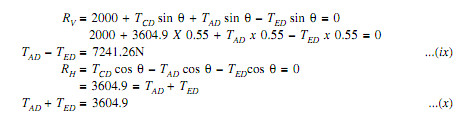

As the four forces are acting at the joint D, So apply resolution of forces at

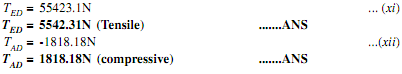

By solving equation (ix) and (x),

|

Member

|

AB

|

BC

|

CD

|

DE

|

DB

|

AD

|

|

Force in N

|

3000.03

|

3000.03

|

3604.9

|

5542.31

|

2000

|

1818.18

|

|

Nature

C = Compression

T = Tension

|

T

|

T

|

C

|

T

|

C

|

C

|