Composite materials consist of two or more distinct components. Generally we refer to a matrix and a reinforcement. The reinforcement can be in the form of fibres (continuous or discontinuous) or particles.

To a reasonable approximation, discontinuous (short) fibre and particulate reinforced composites can be treated by the engineer in the same way as any homogeneous isotropic material. Fibre reinforced composites need to be considered quite differently. In most cases they are still viewed as homogeneous (i.e. the properties in any given direction are an average value), but anisotropy (direction dependence) of properties cannot be ignored.

In general, when working with a continuous fibre reinforced material, the engineer must select the lay-up of composite to be used as part of the design process. The processing route to be used must also be considered at an early stage.

We first consider unidirectional material.

Mechanical Properties of Unidirectional Laminates

Q1 If you are working with a metal, what elastic properties do you need in order to calculate strains (deflections) of a structure under generalised in-plane loading? Write down the stress-strain relationship for an element of material which experiences stresses σx, σy, τxy in an x-y coordinate system.

Q2 What property data do you need (for a metal) in order to ensure that your design loads will not cause plastic deformation (yielding)? What are the most widely used yield criteria?

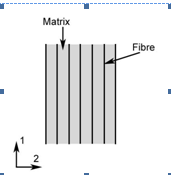

Consider now that you are working with a unidirectional fibre composite material in an engineering application. Conventionally, the direction along the fibres is the '1' direction and perpendicular to the fibres is the '2' direction.

Principal directions in unidirectional laminate.

Q3 What stiffness and strength property data would be needed to carry out a basic static mechanical design on such a piece of composite material?