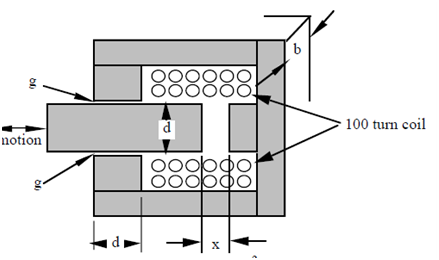

A singly excited magnetic device with a moving iron element is illustrated in the figure below.

g = 0.10 mm

d = 2.0 cm

b = 3.0 cm

Assume the mmf in the iron and the effects of fringing and leakage flux are negligible.

a) Use the force density expression B2/2ì0 to find the force pulling the moving part to the right if B in the center leg is 1.5 T and x = 0.10 mm. Also find the coil current for this condition.

b) Find the force at x =1 mm if the current is held constant at the value in part a.

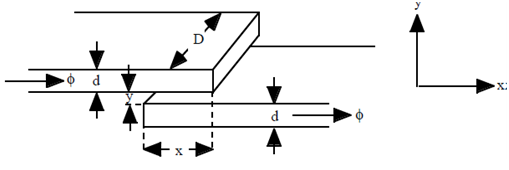

2) Two iron sheets of width D and thickness d overlap by an amount x as shown in the figure. The flux in the upper and lower sheets is and the air gap between the two sheets is y.

Find the flux and the magnetic force(from the derivative of reluctance) in the x and y directions if:

D = 20 cm d = 1 mm y = 1 mm x = 2 cm B = 1.5 T (in iron away from gap)

Neglect fringing, leakage and the mmf in the iron.

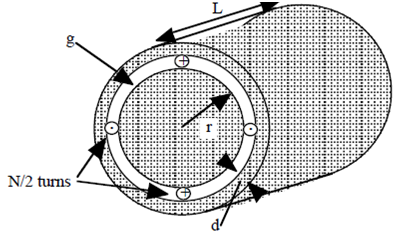

3) Introduction to Rotating Machines

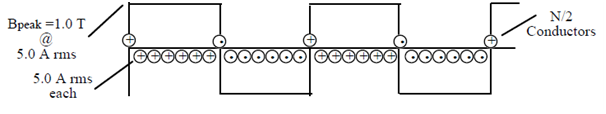

The uniform air gap rotating machine model shown in the figure at the right has a 4-pole concentrated coil winding on the stator with N total turns. When excited with a current of 5.0 A rms at 60 hz the machine has a peak air gap flux density of Bpeak =1.0 T. Assume in all cases that the iron can be considered to have infinite permeability and end effects can be neglected abd that

L = 20 cm r = 10 cm N = 50

a) What would be the peak air gap mmf of this machine? What is the peak value of the spatial

fundamental component of the air gap B -field?

b) What is the peak flux per pole of the machine? What should the width of the yoke 'd' so that the peak flux density in the yoke is the same as in the air gap?

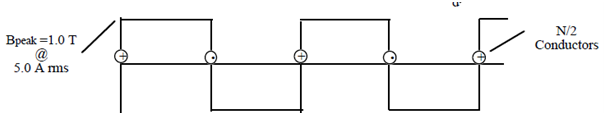

c) What would be the peak torque produced if a uniform distribution of conductors with 100 total conductors (25 for each pole) and carrying the same 5.0 A rms in series with the original winding were added as shown in the figure below? What would be the average torque?

d) If the conductors of this machine are relocated to create a two pole concentrated coil machine, what value of rms current would be needed to give a peak field of 1.0 T? What would be the new 'd' to keep the yoke flux density =1.0 T?

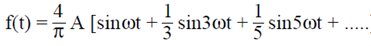

e) Assume two more windings identical with the original 4-pole concentrated coil winding but displaced by 120 electrical degrees (60° mechanical) are added to form a three phase winding. Assuming balanced three phase sinusoidal currents of 5.0 A rms and given that the Fourier series of a rectangular wave is find

the peak amplitude and mechanical rotation speed of the fundamental rotating B-field.