Formula for maximum power transmitted by belt:

Derive formula for maximum power transmitted by belt when centrifugal tension is considered.

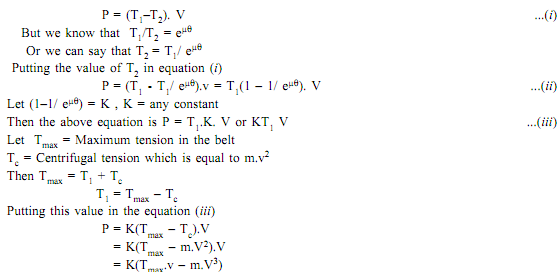

Sol: Let T1 = Tension on tight side T2 = Tension on slack side v = Linear velocity of belt

Then the power transmitted can be given by the equation

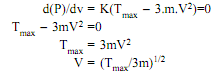

Power transmitted will be maximum if d(P)/dv = 0

Thus differentiating equation with respect to V and equating to zero for maximum power, we get

Equation (iv) gives velocity of belt at which maximum power is transmitted.

From equation (iv) Tmax = 3Tc ...(v)

Hence when power transmitted is maximum, the centrifugal tension would be around 1/3rd of the maximum tension.

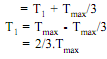

We know that Tmax = T1 + Tc

Hence condition for transmission of maximum power is:

Tc = 1/3 Tmax, and

T1 = 2/3Tmax ...(viii)

NOTE: The net driving tension in the belt = (T1 - T2)