Determine the loss-by-defect and loss-by-dispersion

Given, Annual production = 1,00,000 units

Specification = 20 ± 4 i.e. m = 20, Δ = 4

Cost of repairing or resetting a product out-of-specification is Rs. 100.

a. Process I,

= 20, σ = 1.33

= 20, σ = 1.33

b. Process II,

= 18, σ = 0.66

= 18, σ = 0.66

c. Process III,

= 17, σ = 0.40

= 17, σ = 0.40

Determine the loss-by-defect and loss-by-dispersion.

Solution

Process I

Given specifications 20±4

∴ USL = 24

LSL = 16

Given process average ( ) is mean

) is mean

centred at target m = 20 and σ = 1.33.

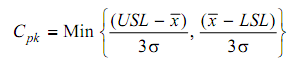

= Min {24 - 20 /3 × 1.33, 20 - 16 /3 × 1.33}

As both values are equal, we might use either of them as minimum value.

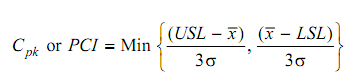

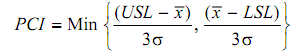

∴ C pk = 4/ (3 × 1.33) = 1

Loss-by-defect

Loss = proportion out of specification × total number × cost of product

= 0.0027 × 1,00,000 × 100

= 0.27 × 1,00,000

Loss-by-dispersion

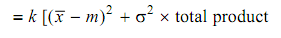

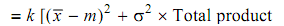

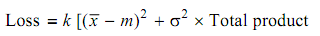

Loss = Loss per piece × number of products

k = A/ Δ2 = 100/42 = 6.2

Process II

∴ Loss = 6.2 [(20 - 20)2 + 1.332] × 1,00,000

= 10.97 × 1,00,000

The process average is observed to be centred at 18 with σ = 0.66

= Min { 24 - 18 /3 × 0.66 , 18 - 16/3 × 0.66}

C pk = 18 - 16 / 3 × 0.66 = 1.01 ≈ 1

Loss-by-defect

Loss = proportion out of specification × total number × cost of product

Standard normal variable at LSL

At USL

Z 1 = 16 - 18/ 0.66

= - 3.03

Z2 = 24 - 18/0.66 = 9.09

∴ Proportion out of specification from tables,

= F (- 3.03) + F (9.09)

= 0.00122 + 0

= 0.00122

∴ Loss = 0.00122 × 100000 × 100

= 0.122 × 105 Rs.

Loss-by-dispersion

Loss = Loss per piece × Number of products

k = A/ Δ2

= 100 = 6.25

∴ Loss = 6.25 [(18 - 20)2 + 0.662] × 1,00,000

= 27.7 × 105

Process III

x = 17, σ = 0.40

= Min {24 - 17/3 ´0.4 , 17 - 16 /3´0.4}

= min {5.83, 0.83}

∴ PCI = 0.83

At LSL Z = 16 - 17 /0.4 = - 2.5

At USL Z = 24 - 17 /0.4 = 17.5

∴ Proportion out of specification, from tables

= F (- 2.5) + F (17.5)

= - F (2.5) + F (17.5)

= 0.00621 + 0

= 0.00621

∴ Loss by defect = Proportion out of specification × Total product

× Cost of product

= 0.00621 × 100000 × 100

= 0.621 × 105

Loss-by-dispersion

= 6.25 [(17 - 20)2 + 0.42] × 100000

= 57.25 × 105