Reference no: EM132279887

Tasks to be undertaken:

AIM

The overall aim of this assignment is to demonstrate that you have a clear understanding of Thermal Analysis and Computational Fluid Dynamics (CFD) Methods, and the role these techniques play in development of heat and mass transfer systems, the benefits associated with their use and the problems and limitations encountered when using these methods.

The above aim is to be achieved through a written report, not exceeding 5000 words.

CASE STUDY 1

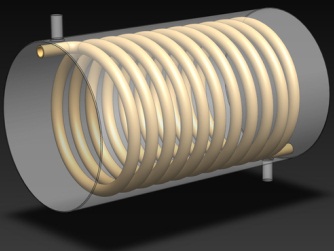

In a heat recovery system, Cold water enters the counter-flow helical heat exchanger at Tc,in oC at a rate of m·A kg/s, where it is used to recover heat from engine oil that enters the heat exchanger at Th,in °C at a rate of m· B kg/s. For the bench mark case use a pitch distance of 100mm for the helical coil.

Each student will generate 2 case studies - A bench mark case which corresponds to the boundary conditions in the table below - ( Use the row that matches the last ID of your student P No). And another case where you optimise the design and operation of the heat exchanger. The objective is to optimise the rate of heat transfer, within the constraints of 1m length and a fixed outer shell diameter of 250mm. Flow rates must be realistic!

Figure 1: Schematic of Heat exchanger

Each student will use the following details for a base case and then optimise the heat transfer

|

Last Digit of

Student ID

|

Tc,in oC

|

Th,in oC

|

m·A kg/s

|

m·B kg/s

|

|

0-1

|

5

|

120

|

4

|

8

|

|

2-3

|

7

|

110

|

4

|

9

|

|

4-5

|

10

|

100

|

4

|

10

|

|

6-7

|

12

|

90

|

4

|

11

|

|

8-9

|

15

|

80

|

4

|

12

|

|

Penultimate Digit

of Student ID

|

Tube diameter

(mm)

|

Shell diameter

(mm)

|

Interface

thickness (mm)

|

|

0-1

|

20

|

250

|

5

|

|

2-3

|

22.5

|

250

|

10

|

|

4-5

|

25

|

250

|

15

|

|

6-7

|

27.5

|

250

|

20

|

|

8-9

|

30

|

250

|

25

|

You will need to work through the following steps

1. Geometry Creation: using Ansys Design Modeller or importing from other CAD software such as Creo, Solidworks. etc

2. Meshing the geometry: (Mesh)

3. Setting the boundary conditions: (setup)

4. Performing the simulation (Solution): Ansys fluent solver (steady state calculation)

5. Post processing the results:

CASE STUDY 2

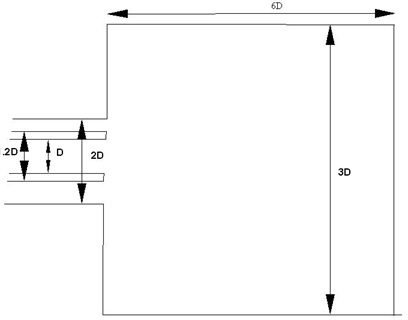

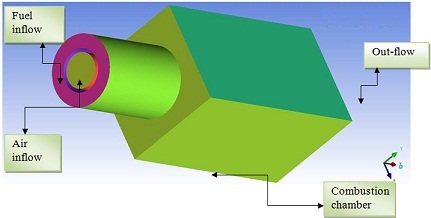

The burner with the dimensions below should be built on meshed and solved in Ansys workbench using a basic combustion model (for methane-air mixture or any other mixture the student may opt to go for should be set in .

Figure 2: Burner Geometry

Last Digit of Student ID D(mm)

0-1 55

2-3 60

4-5 63.5

6-7 65

8-9 70

Figure 3: Burner Geometry 3D