Reference no: EM131277807

Initial Instructions

Modelling within Creo Parametric

Create a bezel part within the design module of Creo Parametric academic addition 2.0 with the overall dimensions as indicated on Figure 1 incorporating the concepts identified.

Design the logo at your own discretion, with the phrase "mcnillis plastics", but check for possible serious problems using Model Check. Generate images throughout; these will be needed for the report section below:

Report

Write a 1000-word report +/- 500 words; the report is expected to show how you proceed through each task where you create your own outputs adding capture screens as figures, explanations and reasons underpinning your approaches and choices. See the "Report Template" attached.

- The information obtained through model check should be included into the report.

- Add borders to the images and centre the images and captions to make it easy for the reader to view.

- Use and reflection on Plastic Advisor as required in Lesson 6; see below for lesson 6:

Lesson 6: Plastic Advisor

Lesson 6.1: Plastic Advisor tutorial

Plastic Advisor is a module accessible through Creo, however to access the module you must have Creo running and an active part or you can open a part file through the normal File Open drop down menu Use the part you created in Lesson 5 to enable you to access Plastics Advisor. To access the Plastics Advisor module click the File drop down menu. move the cursor to Save As and select Plastics Advisor. You can ignore 'Pick datum points for injection locations ...' message by pressing the MMB to bypass selection or by clicking Cancel in the Select window in the top right. This should open Plastic Advisor. From the task bar select the Help drop down menu and then Search Help. The Advisor Homepage window will open. Read all topics in it and focus on Tutorials - Getting started. The Course Map is navigated by clicking the icon. If you get an Internet Explorer Script Error dick yes to continue running the script.

Once you familiarise yourself with the Plastic Advisor functionality you can go through it using your model. One of the benefits of using a module such as Plastics Advisor is you can find and experiment with different injection point locations for best results. Because injection point can leave marks on the part, they are normally sited at locations which will be unseen on the actual product.

Student activity

1. Load the part you created in Lesson 5 into Plastics Advisor and run the Analysis wizard (running man icon). Select Gate location analysis to find the best injection point location. Use the following material specification for your test:

- Plastic Trade Name: Apec 1600

- Generic Family: PC ( Polycarbonate)

- Type: Thermoplastic Copolymer

- Manufacturer. Bayer USA

- Maximum Injection Pressure Limit: 100 Mpa

- Mold temperature: 100 °C.

- Melt temperature: 325 degrees °C.

2. Using the syringe icon pick injection location and (through the wizard again) run a Plastic filling test and capture the results for your report.

3. Identify potential air traps and weld lines:

4. Locate possible sink marks areas on a model:

5. On the bases of the results obtained above, suggest appropriate improvements.

Add this data with screen captures and explanations to help complete your report for assignment CW1.

Unit Aims

1. To learn how to design products using complex 3D CAD, CAM, simulation and analysis software tools in engineering products development.

2. To develop confidence and capability in the effective use of industrial standard CAE software and hardware systems.

3. To understand how integrated engineering software can enhance product development.

Unit Learning Outcomes

1. Apply 3D CAD modelling in engineering design and appraise the ways in which CAD/CAM/CAE integrated computer software packages can be employed to aid the design to manufacture process.

2. Use an integrated 3D CAD/CAM/CAE software package in an interactive and integrative way for the effective solution of real engineering problems.

3. Appraise the machining constraints and economics in the development of product designs for manufacture (coursework 2).

4. Apply modelling and simulation for manufacture in an integrated CAD/CAM environment (coursework 2).

5. Critically analyse the use of integrated 3D CAD/CAM/CAE software in engineering design and manufacture.

Coursework 1 Aim:

To produce and analyse a part model that solves the problems defined below which is suitable for injection moulding.

Background

A bezel shown below (Table 1) is an existing product design that has been machined from an aluminium alloy casting. The function of the bezel is to provide a secure mounting for pairs of transducers that are wired and fastened through apertures. The number of pairs of transducers is determined by the product assembly specification and any apertures not used are sealed with blanking plates. The bezel is fitted to a machined mounting surface and the joint sealed with a thin neoprene gasket. The bezel has a raised lip that correctly locates the part on its mounting surface and it is secured internally with three fasteners. The sealed bezel assembly provides IP55 enclosure protection (Prevents ingress of dripping water).

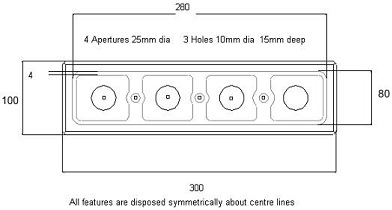

The height of bezel to mounting face is 45 mm and the locating lip 4mm wide extends 4 mm above the mounting face. Sketched Dimensions of the existing aluminium alloy bezel (not to scale) is shown in Figure 1.

Concept

The concept for a new design of bezel part will enable it to be realised as a plastic injection molding. The design must retain all the existing functions of the part but will include features to provide sealing by means of a 4mm diameter nitrile 0-ring set into the sealing face of the bezel rather than use a rubber gasket. The housing face to which the bezel is assembled will not be modified and the bezel will be secured using a similar fastening arrangement. The bezel apertures will be sealed over with a 0.5mm thick membrane as molded, the required apertures broken out on assembly. The general shell thickness of the bezel should be 3mm and the material required to be PC (Polycarbonate). The production moulding will incorporate screwed bushes for securing the bezel.

Coursework

You will create a bezel part within the design module of Creo with the overall dimensions as indicated on Figure 1 incorporating the concepts identified above.

The part will show the necessary features required for product realisation such as drafts and stiffening ribs as appropriate and should be designed in accordance with good industrial practice.

Create your own logo on an appropriate non-functional surface. Check for possible serious problems using Model Check.

You are not required to model the three screwed bushes used for the fastening the bezel, it is sufficient to model holes to locate the screwed bushes with the same dimensions as in the aluminium part but adding appropriate drafts.

There can be a considerable degree of 'flair' in the design activity as it has a creative facet however it is important to recognise that much of the minor detail has no significant bearing on the function of the majority of features. However, it may have a considerable effect on the cost of realisation. To prevent an uncontrolled growth in diversity of feature detail, designers are encouraged to use what are referred to as preferred sizes for which ISO standards exist. Most companies have adopted companywide standards for use internally that are based on a subset of ISO standards.

Trial Bezel shows a raw attempt at designing a part for injection molding and gives an impression of a typical design activity outcome. Please note however that the example shown is only one of many possible modelling solutions.

Coursework

To qualify for a Pass mark the minimum expectation is:

- Design of a 3D CAD model in Creo suitable for plastic injection moulding and according to the specification given above, including Model check;

- Use and reflection on Plastic Advisor as required in Lesson 6;

- Report as per the Assessment section in the Introduction lesson.