Reference no: EM131944216

Question 1

A car company has a requirement of 100,000 hubcaps for their car assembly operation annually. A hubcap is a cover for the wheel hub of a motor vehicle, and is largely a non load bearing part, and made with metallic alloys or non-metallic materials. A typical hubcap (dimensions not important) is shown in the Figure, which costs about $7 per part. Using the principles of manufacturing processes and with the assistance of the Table provided:

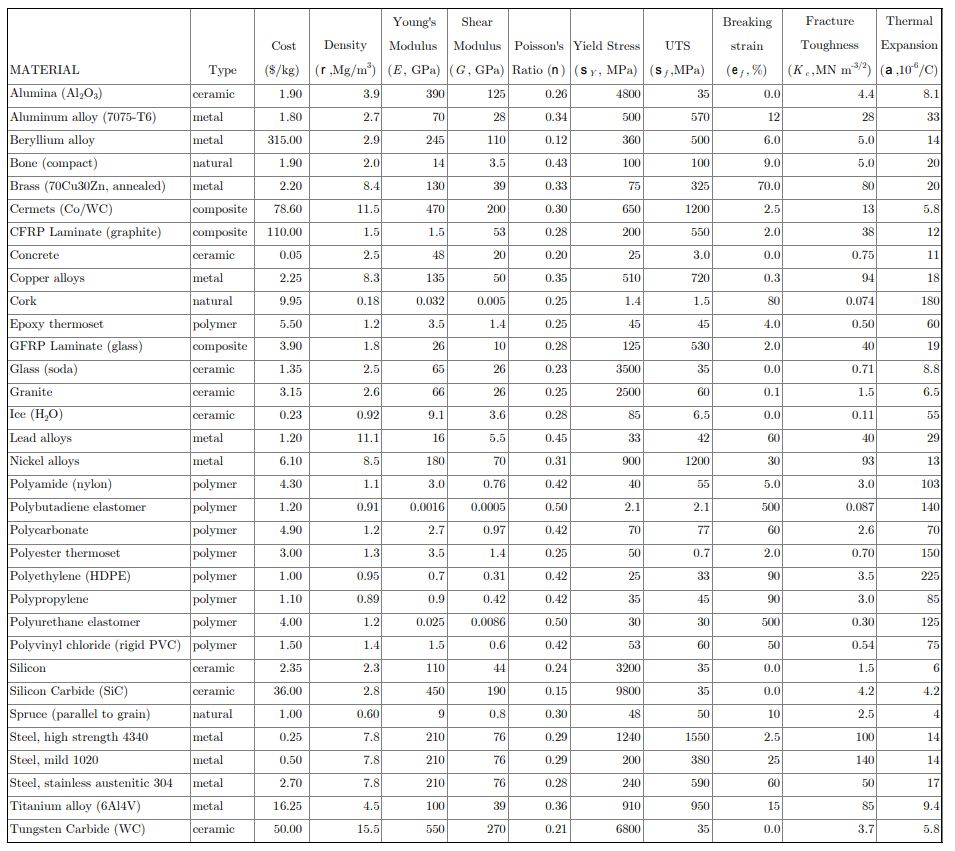

a) Provide a list of 5 design considerations (geometry, finish, mechanical properties, etc.) for manufacturing a hubcap for automobiles. Based on your considerations, recommend i) material, and ii) manufacturing process to be used to manufacture the hubcaps. Provide clear criteria (cost, properties, density, formability, shape, complexities, etc.) to support your choice of material/manufacturing process.

b) For the selected manufacturing method, show (i) necessary material preparation, (ii) the design of the mould or tooling using a freehand sketch, and (iii) stepwise details of processing and finishing operations used to manufacture the hubcaps.

Figure. A generic hubcap used in a motor vehicle (highlighted).

Table: Cost and Properties of Engineering Materials.

Question 2

1. Define the bulk deformation process of Extrusion, and list the 2 main types of extrusion. Explain the relationship between Ram Stroke and Ram Pressure in the 2 main forms of extrusion, and describe the major factors that influence Ram Pressure? List and explain briefly the different defects in extrusion products, and describe how these defects can be minimized?

2. Define the phenomenon of Springback in sheetmetal forming, and provide a detailed explanation of the methods used to compensate for springback in finished sheetmetal products.

3. Why are the parts manufactured using powder metallurgy of near net shape? For mixtures of dissimilar metal powders, explain how (a) blending/mixing, and (b) compaction are carried out before sintering. Explain how (i) blending/mixing and (ii) compaction steps influence the (a) sintering step and (b) porosity development in the processed part.

|

How social and economic factors affect public health program

: Discuss how social and economic factors affect public health programs (local, State, or Federal)? Explain factors include examples of community health services.

|

|

Determine the free cash flow from given years annual reports

: Using the two (2) stocks above identified, determine the free cash flow from 2013 & 2014 annual reports. What inference can you draw from the companies'.

|

|

Identify your strengths and limitations regarding team work

: Identify your strengths and limitations regarding team work. Address what you like most about working with a team. Briefly share what you know about theory.

|

|

Journal entry with the information

: How to begin a journal entry with the following information: author, chapter number, chapter title, pages, and the date composing the entry?

|

|

Define the phenomenon of springback in sheetmetal forming

: MEC2202 - Define the phenomenon of Springback in sheetmetal forming, and provide a detailed explanation of the methods used to compensate for springback

|

|

The motivational levels of criminal justice workers

: Contact your local police chief or sheriff and discuss with them the issues related to motivation in their organization.

|

|

Determine the real assets and liabilities of the company

: Determine the key reasons why accountants, investors, and creditors found it challenging to determine the real assets and liabilities of the company.

|

|

Business assets to another individual

: Many household services professionals such as carpenters, plumbers, and electricians do business as sole proprietors. If they make a promise

|

|

How you could apply the concept analysis to your practice

: Create 18 to 20-slide PowerPoint presentation on the article with detailed speaker notes. Describe how you could apply the concept analysis to your practice.

|