Fatigue

Fatigue is not the property however the behaviour of material under stresses which changes with time. Most interesting thing about fatigue is that a stress level which is below yield or elastic limit is safe if applied once, however if similar level is applied repeatedly upon a specimen then it will fail. Such a failure beneath repeated stressing is called fatigue failure and has discernible characteristics.

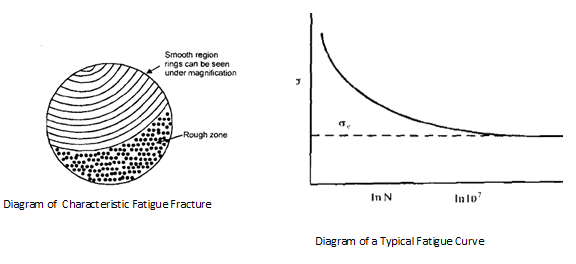

The most significant characteristic of fatigue failure is that it is without perceptible plastic deformation in the region of fracture. Even if the specimen is loaded beneath axial tensile stress that reverses and whose magnitude is below yield strength, the fatigue failure will happen and there will be no necking or elongation in specimen. Fracture surfaces have a characteristic appearance along with rings beneath magnification and rough surface.

The number of cycles after that the specimen fails is failed the fatigue life at the applied stress. If stress level is plotted against in of number of cycles at failure the characteristic fatigue curve is acquired. The curve indicates that at lower stress level the specimen tends to have longer life or even may not fail. All fatigue tests are stopped at 1o7 cycles and a specimen surviving 10 million cycles is regarded survival or non-failure. The stress level at such specimen survives 10 million cycles is called fatigue strength or endurance limit as former denoted by se , is preferably utilized. Fatigue life at specified stress level and fatigue strength are two fatigue properties and they are influenced by several factors as like specimen size, surface finish, temperature, stress concentration, frequency. Smooth polished specimen at frequency less than 1000 cycles/min. And room temperature will contain:

σe = 0.5 σu (steels)

σe = 0.4 σu (non-ferrous)

The fatigue strength is affected by some variables as:

(a) Fine finished surfaces result in high fatigue strength.

(b) Stress concentration decreases fatigue strength however not as much as stress concentration factor.

(c) All treatments that enhance static strength also improve fatigue strength.

(d) Under-stressing is process of stress cycling below fatigue strength. This improves fatigue strength. Slow and regularly increasing cyclic stress up to fatigue strength is coaxing.

(e) Small size specimen or as 6 to 12 millimeter diameter have higher fatigue strength than larger size specimen or as > 6, millimeter diameter, however after 100 millimeter diameter, this effect levels off.

(f) Corrosive atmosphere, high temperature cause reduction in fatigue strength.