Engineering Materials

The materials utilized for tools, structures, machines and other durable goods are usually regarded as engineering material. These materials are classified in different type. Inorganic and organic materials are close to scientific division. Materials of both types are utilized for engineering reasons. Organic substances are generally derived from living organisms and necessarily have carbon (C) as like one constituent. Animal hides as leather, oil as petroleum, wood, some chemicals, paints, manmade polymers and natural resins are illustrations of organic materials, all elements involving metals and their alloys, acids not contain carbon as its constituent, ceramic, non-living natural materials as like sand the rock are viewed as inorganic materials. All types are found in gaseous, and solid and liquid states.

Composites are combination of materials whether neither solution nor chemical reaction happens but properties enhances for engineering purposes purely due to mechanical interaction among the constituents. Both constituents may be organic or inorganic or all. Reinforced concrete is a common illustration while cemented carbide, reinforced plastics tools are composites also. Reduction in weight couple along with high strength and stiffness has opened possibilities of improvement of newer composites.

Due to malleability, ductility, electrical conductivity and strength the metals have become extremely common and dependable engineering martial. Still most metals are elements as Fe, Cu, Al, Zn only some are utilized in practice. Their properties enhance by alloying. The most commonly utilized alloy is steel which has Fe as most important constituent and Si and C as alloying elements in extremely small proportion. Alloys as like steel have become very dependable materials since their properties can be changed by heat treatment.

High temperature application needs the materials to remain enough strong over a wide range of temperature. The borides, oxides, carbides and nitrides of several metallic elements contain high wear resistance, high strength at elevated temperatures however have marked brittleness. Those materials are given as ceramics.

Plastic or Polymers have obtained a great deal of popularity for making parts of complex shapes however not subjected to high loads. Such are organic compounds that made by chemical processes and are utilized in form of fibers, sheets and in different other shapes. Most composites are made utilizing plastics. The composites and plastics contain good resistance against corrosion.

Perhaps the mainly common engineering materials after concrete and bricks are alloys. Steel is the foremost illustration. The elemental metals are mixed in liquid state or heated to liquid state whereas they may have partial or total solubility and on cooling the solids may have partial or total solubility. Combination of two or more metals produce alloys in solid state in most cases them possess properties better than the constituents. Symmetry diagrams sketched among temperature as ordinate and % age composition of one of the two constituents provide great deal of information about alloys. At any temperature number of phases and their chemical composition can be found from phase or equilibrium diagrams.

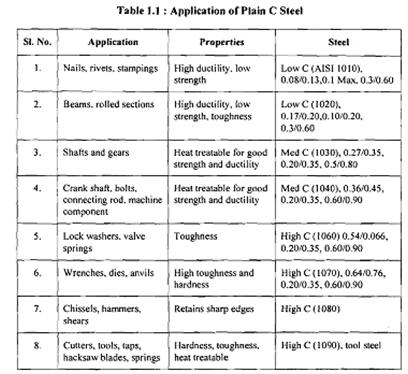

Pure and clean Iron may contain 99.99% iron which could be produced by very expensive electrolytic process. Although not good for much strength, pure iron is utilized for research transformer cores. Commercial iron might 99.99% pure. While bring expensive it is used for special purposes for high corrosion resistance and electrical conductivity. Wrought iron has about 3% slag particles distributed uniformly in iron matrix. 'The presence of slag is useful in increasing resistance against fatigue and corrosion. This material is utilized for stream oil and water pipelines. The alloys of iron containing upto 2% carbon with small amount of S, Si and P and Mn are classified as steel. Cost iron is now another alloy of iron containing more than 2% of carbon.

Composition in %of Carbon, Si, Mn or in this order with Max P-0.04% and Max S-0.05