Die Block

The design of die block depends upon workpiece size & thickness. The category of die and contour of workpiece also play a significant role although designing of the die block. The selection of size of die block also depends upon experience. The die blocks are made from a solid block of tool steel for small workpieces. Table provides die block thickness with respect to strip thickness. The distance among the die opening and outside edge of the die block should be 1.25 times a thickness of the die block for smaller dies.

Table: Die Block Thickness for Mild Steel Strip

|

Strip Thickness (inch)

|

Die Block Thickness (inch)

|

|

Up to 1/16

|

3/4 to 1

|

|

1/16 to 1/8

|

1 to 9/8

|

|

1/8 to 3/16

|

9/8 to 11/8

|

|

3/16 to 1/4

|

11/8 to 13/8

|

|

Over 1/4

|

13/8 to 2

|

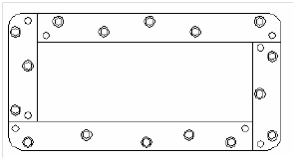

This distance should be 1.5 to 2 times the die thickness for big dies or when sharp corners are present within the die opening contour. The solid blocks which are symmetrical face the problem of incorrect assembly that can be prevented through fool proofing the die block. Fool proofing is achieved through placing one dowel at some other distance from its nearest screw hole. It is possible to save a large amount of material through using insert dies in the construction of die blocks. In the construction of huge die block or the complex contour die, die blocks are made in two or more sections in order to save the tool steel. The die may also be sectioned while the size of the die opening is not large sufficient to permit internal machining. In case of failure, only one component requires to be replaced and thus, it is one of the advantages of sectional die blocks. Figure shows the technique of sectioning large die. Sectional components might be screwed and doweled to a die holder with sections butting against each other. These sections are huge sufficient to prevent tilting.

Figure: Method of Sectioning Large Die

Sometimes sectional elements are used to tip other components to prevent lateral displacement of the die sections. This lateral displacement is because of heavy cutting force. This arrangement decreases the cutting forces.