Deflection due to Compliance of the Tapered Joint

The spindle ends of several machine tools have a tapered hole for accommodating a center (in lathe) or cutting tool shanks (in milling and drilling machine). The deflection of center or shank at a distance d from the spindle axis in which the force F is acting is expressed by equation:

Where

d3 = Δ+ φ d

Δ stands for displacement of the shank or center at the edge of taper because of contact compliance, and

φ stands for angle of slope of the shank or at the edge of taper.

If manufacturing the errors of the taper are ignored, Δ and φ can be computer from subsequent equations:

Δ = 4ΨDC1 / πD (Ψd C2 + C3), μm

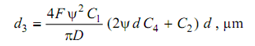

Φ = 4FΨ2C1 / πD (2Ψd C4 + C2)

Where

C1 stands for coefficients of contact compliance

C2, C3, C4 stands for coefficients that account for the diameter variation along the length of taper.

Ψ = (1/2.3C1D4)1/4 , cm-1

D and d are expressed in cm (centimeter).

Usually displacement Δ because of contact compliance can be ignored in comparison with the displacement because of bending of the shank or center.

Equation

Hence