Thrust augmentation:

There are occasions when the maximum thrust from a basic gas turbine engine is inadequate and some method of increasing the available thrust is required without resorting to a larger engine with its concurrent penalties of increased frontal area, weight and fuel consumption.

There are two recognised methods of augmenting this maximum thrust:

a. De-mineralised Water or water/Methanol injection to restore, or even boost, the thrust from a gas turbine operating from hot and high altitude airfields.

b. Reheat (or afterburning) to boost the thrust at various altitudes, especially at high speeds. This is normally for short periods only.

WATER INJECTION

The power output from a gas turbine engine depends upon the weight (air density) of the airflow and the amount that it is accelerated as it flows through the engine. Therefore, it follows that any condition that reduces the air density will reduce also the engine power output. The two main natural causes of reduced air pressure are:

• Increased Altitude

• Increased Temperature

When these two causes of reduced air density are combined at a high altitude/ tropical airfield, there is a possibility that engines may not produce sufficient power for a safe take-off and climb out. However, in these circumstances, the engine power can be restored and in some instances increased, by cooling the airflow to increase its density. To date, the addition of water or a water/methanol mixture has proved to be the cheapest practical means of restoring or increasing the power of an engine. Methanol has anti-freezing properties and it is also a fuel; therefore water/methanol increases the density of the airflow and provides the extra fuel necessary to match the increased weight of air. Adjustments to the engine fuel system are, therefore, unnecessary. The addition of water has two effects upon the performance of the engine: the cooling effect of water increases the density of the airflow to increase the thrust and, when the water is converted into steam, it provides a high volumetric expansion that increases the thrust even further.

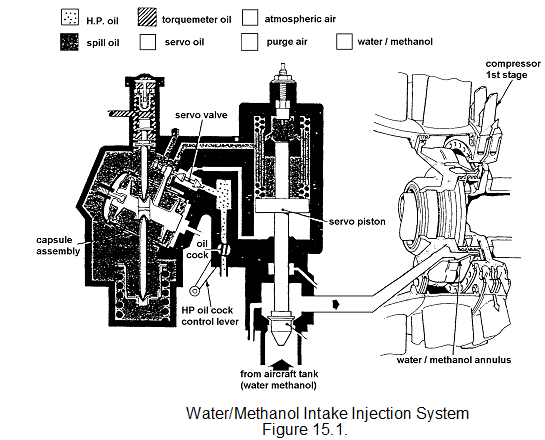

METHODS OF APPLYING WATER/METHANOL

The following notes describe two methods of using water/methanol as a means of restoring lost engine power, or as a means of increasing the total useful power obtainable from a gas turbine engine. The water/methanol mixture can be

• Injecting as a spray into the compressor air intake.

• Injecting direct into the combustion chamber.

Spraying the mixture into the air intake is more effective for engines with centrifugal compressors than it is for axial compressors. With centrifugal compressors, an even distribution of the mixture is obtained whereas, with an axial flow compressor, even distribution is uncertain. (Turbo propeller engines use intake injection regardless of the type of engine in use).

Water/methanol injection into the combustion chamber used to be carried out on older engines where the combustion chambers were relatively long and the methanol had time to separate and burn before entering the turbine. Later engines use water only and increase the fuel flow to gain the extra thrust.

COMPRESSOR INTAKE INJECTION (TURBO PROP)

When water or water/methanol mixes with the air at the compressor intakes, the temperature of the air is reduced and, as a result, the air density, mass airflow and thrust are increased. If water alone were to be injected, it would reduce the turbine inlet temperature and permit an increased fuel flow to be used. When methanol is added, the turbine inlet temperature is partially restored by burning the methanol in the combustion chamber; this restores the engine power without adjusting the fuel flow.