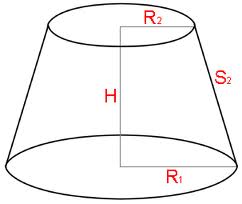

Position of centre of gravity of the frustrum of a cone:

situate the position of C. G. of the frustrum of a cone with height H = 12 cm and with diameter 8 cm and 12 cm at top and bottom, respectively, of the frustrum of the cone as shown in Figure (a).

Solution

Generators B1 T1 & B2 T2 is extended to meet at A.

The volume V of the frustrum T1 T2 B2 B1 of a cone may be assumed as (V1 - V2),

Where V1 = volume of cone B1 B2 A and V2 = volume of cone T1 T2 A as illustrated in Figure (b).

Let similar triangles ATT2 and ABB2

T T2 / B B2 = AT/ A B = 4 / 6

∴ 4/6 = H 2 / (H + H 2)

4 (12 + H 2 ) = 6 H 2

∴ H 2 = 24 cm

∴ H1 = Height of full cone = 24 + 12 = 36 cm

∴ V1 =1/3 π r12 H1 = (π × 36 × 36)/3 = 432 π cm3

Likewise,

V2 =(1/3) π 42 × 24 = 128 π cm3

∴ V = (432 - 128) π = 304 π cm3

Considering moments about the axis B1 B B2,

304 π × z¯ = 432 π( 36/4) - 128 π (6 + 12)

∴ z¯ = 5.21 cm