Plastics, Reinforced Plastics And Adhesives

Introduction

Organic materials particularly that occur in nature like wood and leather have been employed for engineering causes. The modern developments whereby weight reduction, easy fabrication, corrosion resistance and superior appearance are being attained have focused attention on the materials termed as plastics.

Plastic is utilized as a class name for a group of materials such can be formed or moulded into several shapes. Plastics are synthetic materials and chemically they relate to yet larger group of materials termed as polymers.

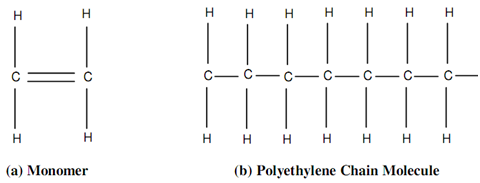

Polymers are materials of complicated nature consisting of various units typically joined in a chain as like structure. The word mer in Greek implies a unit. A monomer is a one unit. Various monomers join together to make a polymer. As an illustration one can consider a polymer termed as polyethylene in given figure.

Figure: Polyethylene Polymer

The section that is repeated in polyethylene is C2H4 or ethylene.

Polymers are categorized into three broad divisions, name are: elastomers, fibres and plastics. We will seem the properties and applications of plastics that have now become very commonly utilized engineering materials. Even if much less in strength than metals, plastics are mostly preferred for their low density. Additionally a lot of plastics can be machined simply; they have good surface finish and are not corroded in environment. Plastics do not conduct electricity and thus are employed in domestic electrical fittings. They are increasingly being employed for furniture, piping, and interiors of airplanes, cars and buildings. The mechanical strength of plastics is mostly improved via reinforcing them along with fibres which has specified rise to a various class of materials termed as reinforced plastics. These materials contain very good strength for low density. As before as in 1960 year an average car employed only 12 kgf of plastic that increased to 100 kgf in eighties and as greatly as to 150 kgf in nineties. Additionally, to above properties and ease of assembly, elimination of surface finishing, reduction of vibration and noise and low cost form them very popular in engineering applications of mechanical.