Master Production Schedule:

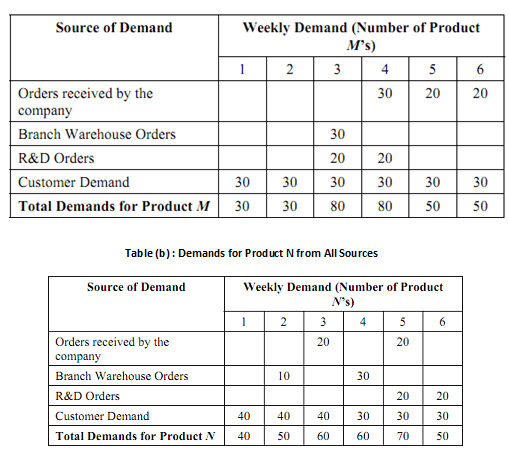

A manufacturing unit produces two products M and N on generates to stock basis. The estimated demand for the product M and N over the next six week are illustrated in the following Tables (a) and (b).

Table (a) : Demands for Product M from All Sources

The amount for the safety stock for product M is 50 and for product N is 40. The fixed lot size for M is equal to 70 and for N are 80. The starting inventory for M is 90 and for N are 70. Make a Master Production Schedule (MPS) for the product M and N.

Solution

For both of products M and N, take the total demands, consider straining inventory, determine in which weeks ending inventory would fall below the safety stock and therefore require production and schedule a lot of the product to be generates during those weeks.

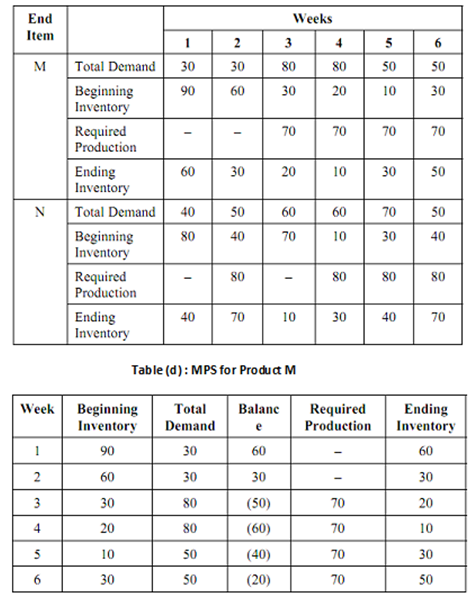

Table (c): Master Production Schedule (Number of Product M and N)

In week 1, the balance exceeds the wanted safety stock; thus no production of product M is needed.

In week 2, the balance is also adequate to provide the desired safety stock and no production of product M is needed.

In week 3, the balance would be negative in fact if production of M where not scheduled thus a fixed lot size of 70 product M is scheduled in third week.

In week 4, the balance would actually be negative if production of M where not scheduled thus a fixed lot size of 70 product M is scheduled in fourth week.

In week 5, actually the balance would be negative if production of M where not scheduled hence a fixed lot size of 70 product M is scheduled in fifth week.

In week 6, the balance would be negative actually if production of M where not scheduled hence a fixed lot size of 70 product M is scheduled in sixth week.

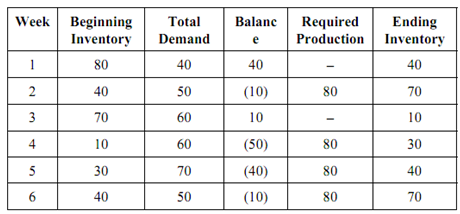

Table (e) : MPS for Product N

In week 1, the balance exceeds the wanted safety stock; therefore no production of product N is needed.

In week 2, the balance would actually be negative if production of N where not scheduled hence a fixed lot size of 80 product N is scheduled in second week.

In week 3, the balance is also sufficient to provide the desired safety stock and no production of product N is needed.

In week 4, actually the balance would be negative if production of N where not scheduled hence a fixed lot size of 80 product N is scheduled in fourth week.

In week 5, the balance would actual negative if production of N where not scheduled hence a fixed lot size of 80 product N is scheduled in fifth week.

In week 6, the balance would actual negative if production of N where not scheduled hence a fixed lot size of 80 product N is scheduled in sixth week.