Inlet duct arrangement in Aircraft Engine:

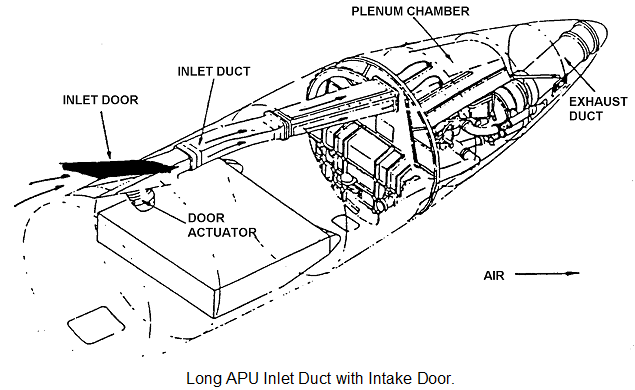

Wherever the APU is located, ducting will be required to bring air to the APU inlet. In figure 18.9. we can see that the inlet duct connecting the inlet door to the APU plenum chamber is divided into three parts. The plenum chamber has the APU inlet duct bolted to its structure, thus reducing a complicated duct joint arrangement. These ducts can be manufactured from various materials, but the most common are aluminium, titanium, steel or composite (fibre glass/carbon). Figure 18.8. shows a light alloy side mounted intake duct without an intake door.

When the duct length is short, steel or titanium ducts may be used. When ducts cover a large distance an unacceptable weight problem may result. Ducts of this length are therefore manufactured from light alloy or composite materials.

One of the main problems of APU's is the ingestion of foreign objects this can be eliminated by fitting wire mesh grills either in the ducting, or around the APU air inlet.

The length of the inlet ducts will depend upon the location of the APU and its distance from the inlet. Some APU inlets are fitted with a door, these are usually forward facing or top mounted inlets. The door will open before the APU starts and close after a time delay on APU shut down The duct may be short or fairly long as shown in the figure.

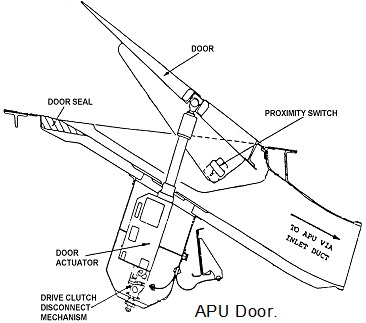

Operation of the door opening and closing is achieved by using an electrical actuator, which receives its signal from a command from the flight deck APU switch.

In the event of an electrical failure to an actuator, there is normally incorporated into the actuator a means of disengaging the clutch drive mechanism. This enables the actuator to be manually turned to open or close the inlet door.

A proximity switch ensures that the door is fully open before the APU start sequence is initiated.

APU inlet doors serve three functions:

• They seal off the inlet duct from harmful weather conditions and foreign objects when the APU is not in use.

• They open to allow air into the APU when the start sequence is initiated.

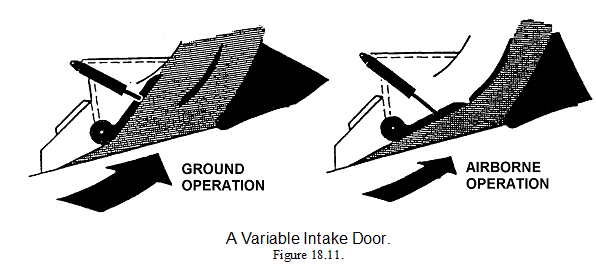

• They can be used to adjust the intake area when on ground in flight.

The variable intake door figure 18.11. is used to reduce the ram air entering the APU intake ducting. This could effect the APU fuel system if intake pressure is not taken into the calculation of engine fuel scheduling which is the case with most APU's .