Engine lubrication systems

There are basically two types of lubrication system at present in use in gas turbine engines:-

a) Recirculatory. In this system, oil is distributed and returned to the oil tank by pumps. There are two types of recirculatory system:-

(i) Pressure relief valve system.

(ii) Full flow system.

b) Expendable. The expendable or total loss system is used on some small turbo-jet engines, eg. RB 162 in which the oil is spilled overboard after lubricating the engine.

PRESSURE RELIEF VALVE RE-CIRCULATORY SYSTEM

In the pressure relief valve type of recirculatory lubrication system the flow of oil to the various bearings is controlled by a relief valve which limits the maximum pressure in the feed line. As the oil pump is directly driven by the engine (by the HP spool in the case of a multi-spool engine), the pressure will rise with spool speed. Above a pre-determined speed the feed oil pressure opens the system relief valve allowing excess oil to spill back to the tank, thus ensuring a constant oil pressure at the higher engine speeds.

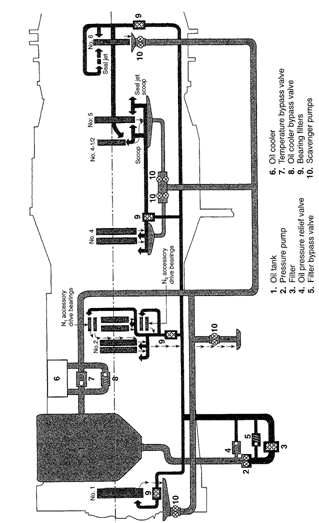

A typical relief valve type of recirculatory lubrication is shown in the figure.

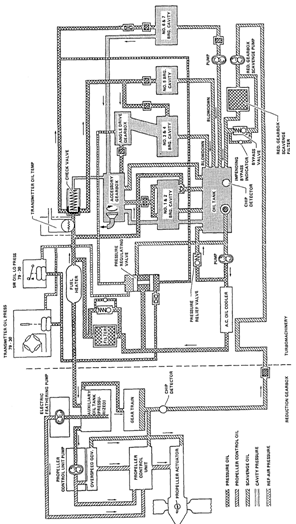

The oil system for a typical turbo-prop engine is similar but, as it supplies the propeller control system, it is more complicated. The oil supply is usually contained in a combined tank and sump formed as part of the external wheelcase. Oil passes via the suction filter to the pressure pump, which pumps it through the air-cooled oil cooler to the pressure filter. A pressure regulating valve upstream of the filter controls the oil pressure. Both oil pressure and temperature indications are transmitted to the cockpit. The oil flows through pipes and passages to lubricate the main shaft bearings and wheelcases. The main shaft bearings are normally lubricated by oil jets and some of the heavier loaded gears in the wheelcases are also provided with oil jets, while the remaining gears and bearings receive splash lubrication.

An additional relief valve is fitted across the pump in the lubrication system of some engines to return oil to pump inlet if the system becomes blocked.

RECIRCULATORY OIL SYSTEM - FULL FLOW TYPE

The full flow lubrication system is an alternative to the pressure relief valve oil system and full flow systems are in use as a means of lubricating many modern high power gas turbine engines.

The full flow system is similar in many ways to the pressure relief system just discussed - i.e. oil is drawn from a tank by a pump and delivered, via a pressure filter, to various parts of the engine; the oil is then returned by scavenge pumps, via the oil cooler to the tank; also, air is separated from the oil by a de-aerator and centrifugal breather.

The major differences from the pressure relief type of recirculatory system are as follows:-

- The flow of oil to the bearings is determined by the speed of the pressure pump, the size of the oil jets and the pressure in each of the bearing housings.

- A metered spill of feed oils is fed back to the tank. This spill is calibrated to match the pump output to ensure that the oil flow to the bearings, via the oil jets, is the same at all engine speeds.

- The relief valve in this system is set to prevent excessive oil pressure in the feed side of the system.

- A filter by-pass is not normally fitted. The pressure drop across the filter is sensed by a differential pressure switch, any increase in the pressure difference being indicated to give advance warning of a blocked filter.