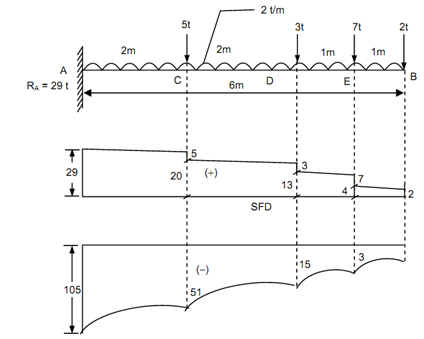

Draw bending moment diagram for the beam:

A cantilever beam carries a uniformly distributed load of 2 t/m over the total length of 6 m and point loads of 5 t, 3 t, 7 t & 2 t at a distance of 2 m, 4 m, 5 m, & 6 m, respectively from the fixed end. Draw BMD & SFD for the beam.

Solution

Reaction at the support A, RA = + 5 + 3 + 7 + 2 + (2 × 6) = 29 t

Shear Force : Starting from end A, SF at A, RA = 29 t

SF just left of C = + 29 - 2 × 2 = + 25 t

SF just right of C = + 25 - 5 = + 20 t

SF just left of D = + 20 - 2 × 2 = + 16 t

SF just right of D = + 16 - 3 = + 13 t

SF just left of E = + 13 - 2 × 1 = + 11 t

SF just right of E = + 11 - 7 = + 4 t

SF just left of B = + 4 - 2 × 1 = + 2 t

SF just right of B = + 2 t (considering right side)

Figure

Bending Moment : Starting from B,

BM at B, MB = 0

BM at E, ME = - 2 × 1 - 2 × 1 × (½) = - 3 t m

BM at D, MD = - 2 × 2 - 7 × 1 - 2 × 2 ×(2/2) = - 15 t m

BM at C, MC = - 2 × 4 - 7 × 3 - 3 × 2 - 2 × 4 ×(4/2) = - 51 t m

BM at A, MA = - 2 × 6 - 7 × 5 - 3 × 4 - 5 × 2 - 2 × 6 ×(6/2) = - 105 t m.