Reference no: EM131154370

1. Various financial data for the past two years follow.

|

|

|

LAST YEAR

|

THIS YEAR

|

|

Output:

|

Sales

|

$

|

200,005

|

$

|

201,025

|

|

Input:

|

Labor

|

|

31,000

|

|

40,001

|

|

|

Raw materials

|

|

35,105

|

|

45,605

|

|

|

Energy

|

|

5,005

|

|

6,005

|

|

|

Capital

|

|

50,005

|

|

50,100

|

|

|

Other

|

|

2,005

|

|

3,050

|

|

a. Calculate the total productivity measure for this company for both years. (Round your answers to 2 decimal places.)

b. Calculate the partial productivity measures for labor, capital, and raw materials for this company for both years. (Round your answers to 2 decimal places.)

2. A parcel delivery company delivered 103,650 packages last year, when its average employment was 86 drivers. This year the firm handled 112,650 deliveries with 97 drivers.

What was the percentage change in productivity over the past two years? (Negative values should be indicated by a minus sign. Round your answer to 2 decimal places.)

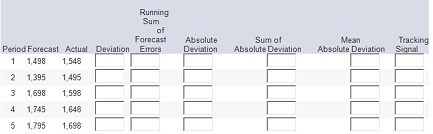

3. The following table shows predicted product demand using your particular forecasting method along with the actual demand that occurred:

|

FORECAST

|

ACTUAL

|

|

1,498

|

1,548

|

|

1,395

|

1,495

|

|

1,698

|

1,598

|

|

1,745

|

1,648

|

|

1,795

|

1,698

|

|

a. Compute the tracking signal using the mean absolute deviation and running sum of forecast errors.(Negative values should be indicated by a minus sign. Round your "Mean Absolute Deviation", "Tracking Signal" to 2 decimal places and all other answers to the nearest whole number.)

4. Assume that your stock of sales merchandise is maintained based on the forecast demand. If the distributor's sales personnel call on the first day of each month, compute your forecast sales by each of the three methods requested here.

|

|

ACTUAL

|

|

June

|

134

|

|

July

|

174

|

|

August

|

204

|

a. Using a simple three-month moving average, what is the forecast for September? (Round your answer to 2 decimal places.)

b. Using a weighted moving average, what is the forecast for September with weights of 0.40, 0.50, and 0.10 for June, July, and August, respectively? (Round your answer to 2 decimal places.)

c. Using single exponential smoothing and assuming that the forecast for June had been 122, forecast sales for September with a smoothing constant alpha of 0.40. (Round your answer to 2 decimal places.)

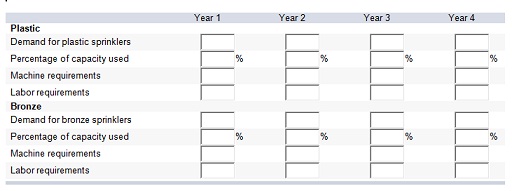

5. AlwaysRain Irrigation, Inc., would like to determine capacity requirements for the next four years. Currently two production lines are in place for making bronze and plastic sprinklers. Three types of sprinklers are available in both bronze and plastic: 90-degree nozzle sprinklers, 180-degree nozzle sprinklers, and 360-degree nozzle sprinklers. Management has forecast demand for the next four years as follows:

|

|

YEARLY DEMAND

|

|

|

1 (IN 000s)

|

2 (IN 000s)

|

3 (IN 000s)

|

4 (IN 000s)

|

|

Plastic 90

|

31

|

|

44

|

|

56

|

|

54

|

|

|

Plastic 180

|

11

|

|

15

|

|

17

|

|

14

|

|

|

Plastic 360

|

44

|

|

56

|

|

65

|

|

67

|

|

|

Bronze 90

|

8

|

|

7

|

|

11

|

|

13

|

|

|

Bronze 180

|

2

|

|

6

|

|

4

|

|

10

|

|

|

Bronze 360

|

10

|

|

12

|

|

16

|

|

14

|

|

|

Both production lines can produce all the different types of nozzles. The bronze machines needed for the bronze sprinklers require two operators and can produce up to 13,000 sprinklers. The plastic injection molding machine needed for the plastic sprinklers requires five operators and can produce up to 200,000 sprinklers. Three bronze machines and only one injection molding machine are available.

What are the capacity requirements for the next four years? (Assume that there is no learning.) (Enter the demand values in thousands. Round your answers to 2 decimal places.)

6. Expando, Inc., is considering the possibility of building an additional factory that would produce a new addition to their product line. The company is currently considering two options. The first is a small facility that it could build at a cost of $7 million. If demand for new products is low, the company expects to receive $9 million in discounted revenues (present value of future revenues) with the small facility. On the other hand, if demand is high, it expects $14 million in discounted revenues using the small facility. The second option is to build a large factory at a cost of $8 million. Were demand to be low, the company would expect $9 million in discounted revenues with the large plant. If demand is high, the company estimates that the discounted revenues would be $13 million. In either case, the probability of demand being high is .30, and the probability of it being low is .70. Not constructing a new factory would result in no additional revenue being generated because the current factories cannot produce these new products.

a. Calculate the NPV for the following: (Leave no cells blank - be certain to enter "0" wherever required. Enter your answers in millions rounded to 1 decimal place.)

|

Plans

|

NPV

|

|

Small facility

|

$

|

million

|

|

|

Do nothing

|

|

million

|

|

|

Large facility

|

|

million

|

|

b. The best decision to help Expando is

•to do nothing.

•to build the small facility.

•to build the large facility.

7. Schedule the following activities using CPM:

|

ACTIVITY

|

IMMEDIATE PREDECESSOR

|

TIME (WEEKS)

|

|

A

|

-

|

3

|

|

B

|

A

|

5

|

|

C

|

A

|

4

|

|

D

|

B

|

3

|

|

E

|

C D D

|

6

|

|

F

|

D

|

4

|

|

G

|

F

|

3

|

|

H

|

E G G

|

5

|

|

b. What is the critical path?

•A-C-E-F-G-H

•A-B-D-F-G-H

•A-B-D-E-H

•A-C-E-H

c. How many weeks will it take to complete the project?

d. Which activities have slack, and how much?

•E, 1 week H 3 weeks.

•B, 2 weeks D 1 week.

•C, 5 weeks E 1 week.

8. The following represents a project that should be scheduled using CPM:

|

|

IMMEDIATE

|

TIMES (DAYS)

|

|

ACTIVITY

|

PREDECESSORS

|

a

|

m

|

b

|

|

A

|

-

|

1

|

4

|

7

|

|

B

|

-

|

3

|

5

|

10

|

|

C

|

A

|

2

|

5

|

8

|

|

D

|

A

|

4

|

6

|

11

|

|

E

|

B

|

1

|

2

|

3

|

|

F

|

C, D

|

3

|

5

|

7

|

|

G

|

D, E

|

1

|

2

|

6

|

|

H

|

F, G

|

2

|

5

|

6

|

b. What is the critical path?

•A-C-F-H

•B-E-G-H

•A-D-F-H

•A-D-G-H

c. What is the expected project completion time? (Round your answer to 3 decimal places.)

d. What is the probability of completing this project within 22 days? (Do not round intermediate calculations. Round your answer to 4 decimal places.)